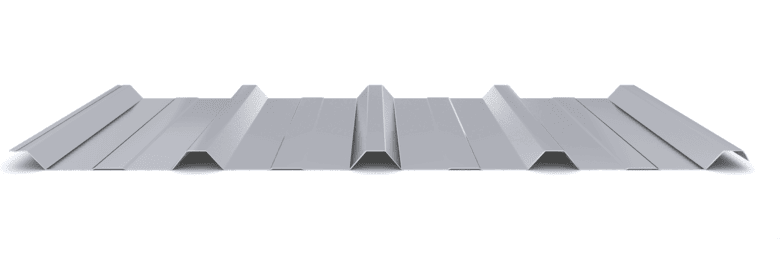

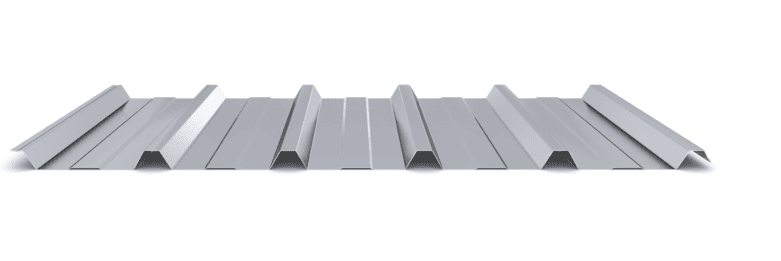

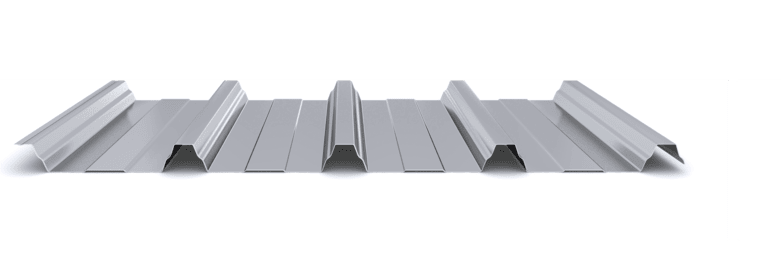

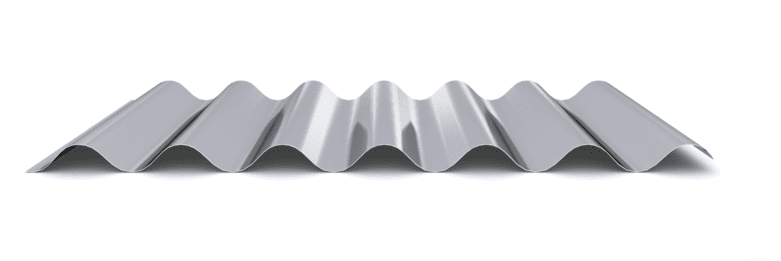

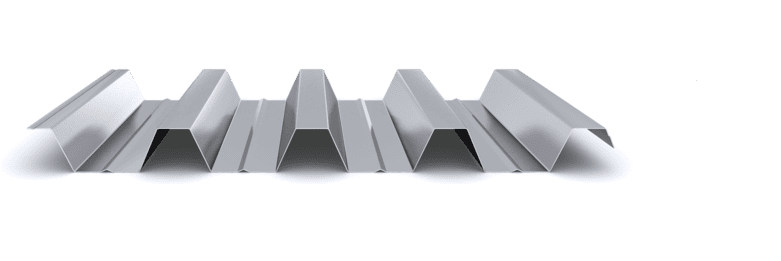

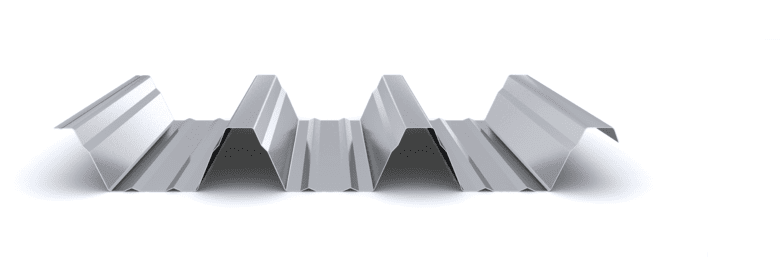

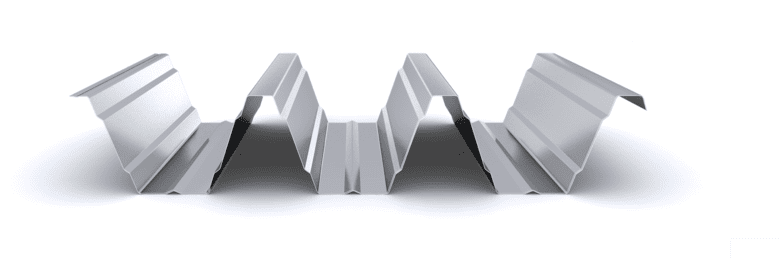

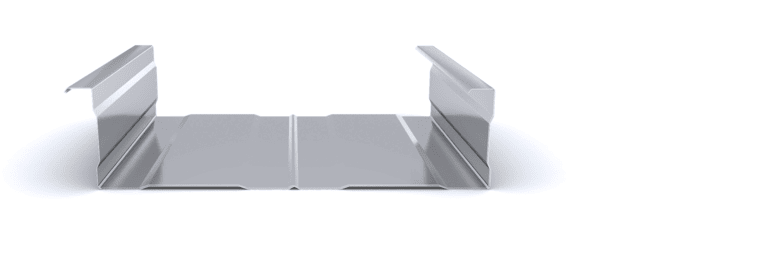

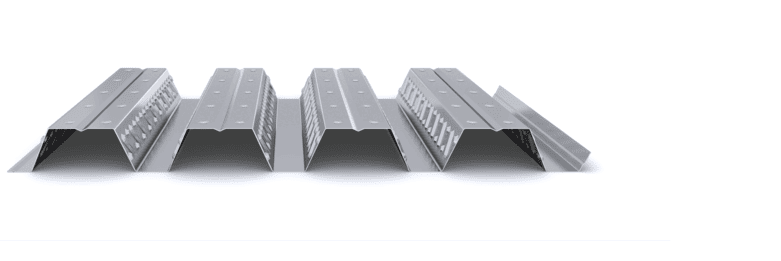

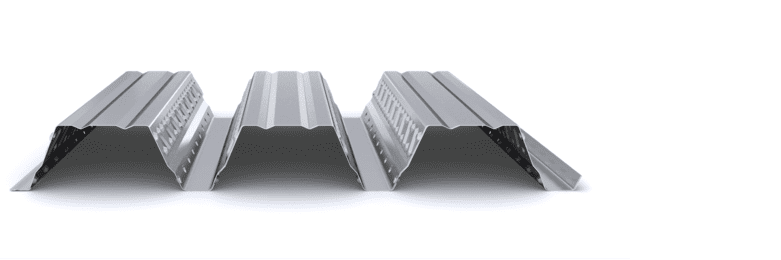

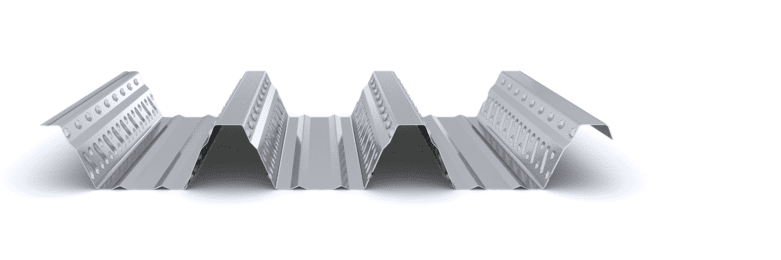

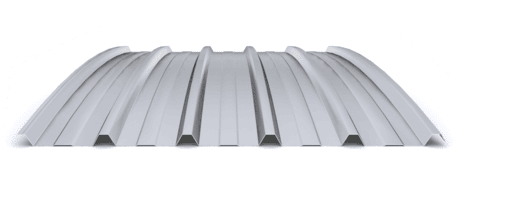

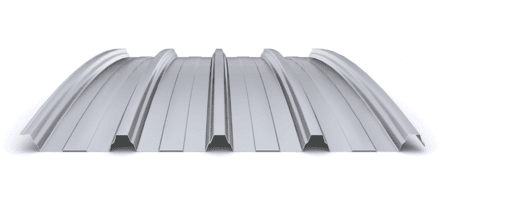

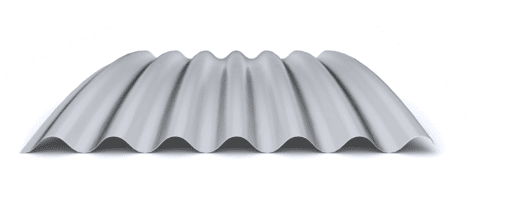

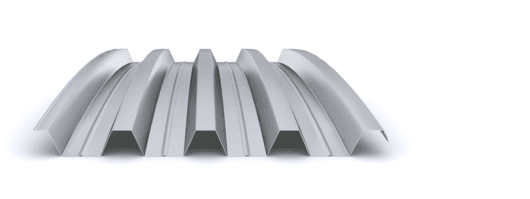

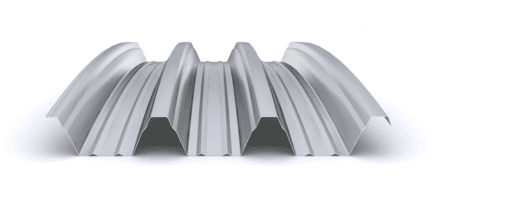

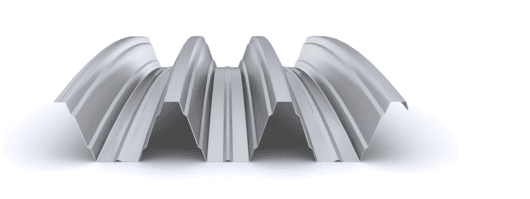

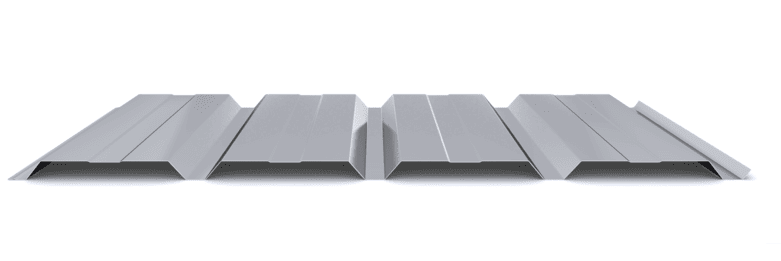

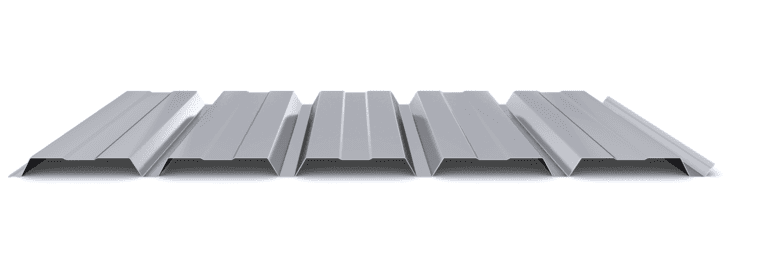

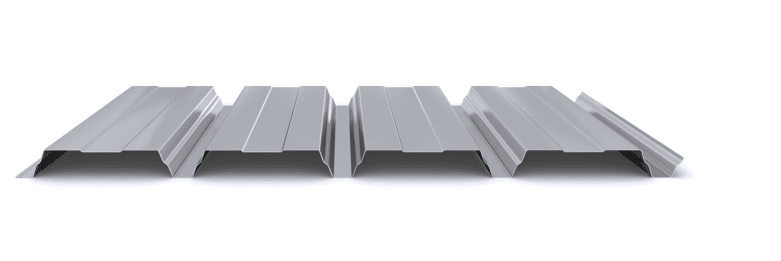

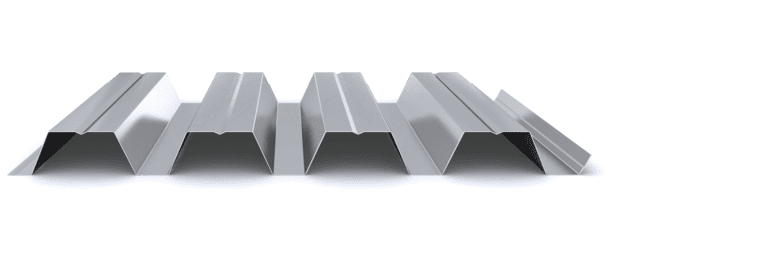

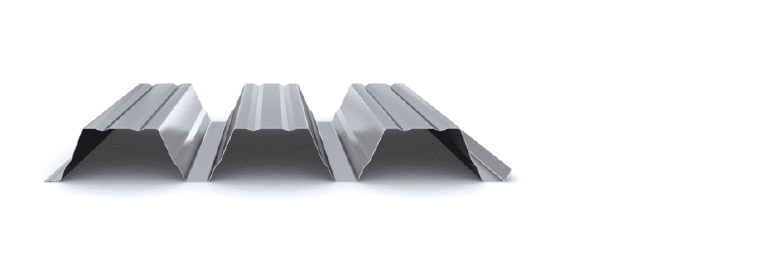

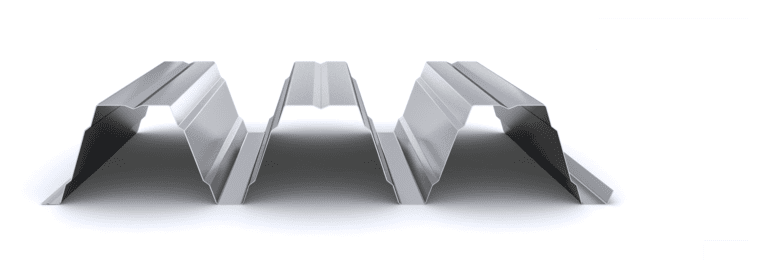

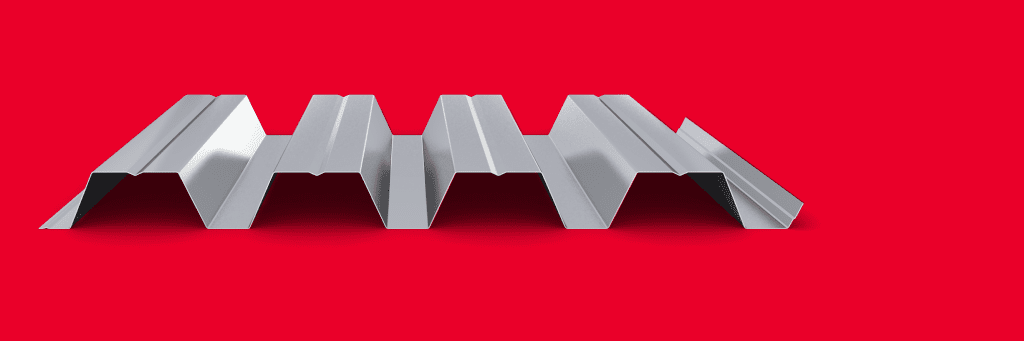

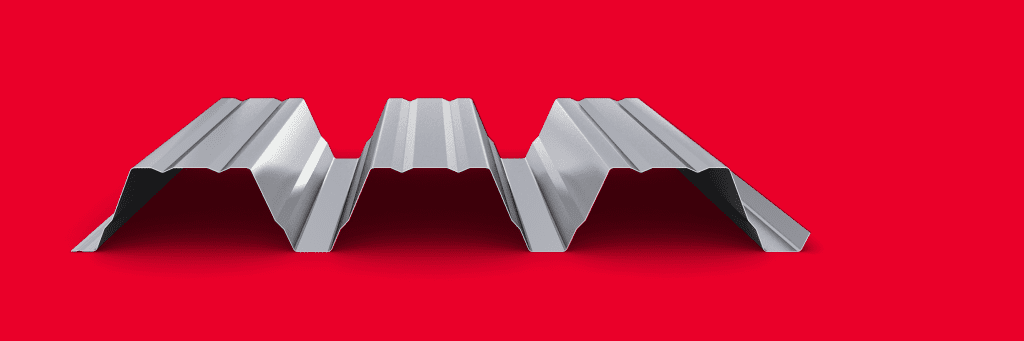

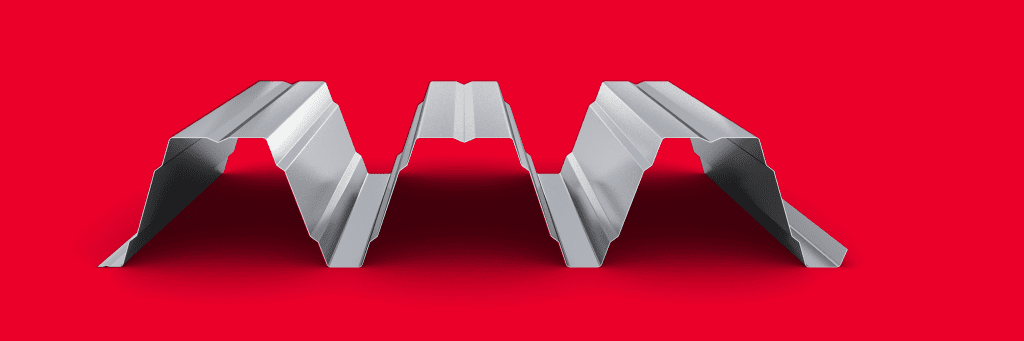

The lost formwork system consists of a galvanized steel ribbed profile that serves as formwork for a concrete slab executed in situ. The main function of the corrugated profile is to support the loads of execution and pouring of concrete, avoiding the need for shoring.

Unlike the composite slab solution, in the lost formwork solution the profiles do not have inlays and do not subsequently collaborate with the concrete slab. Due to this lack of contribution from the sheet metal, the use of positive reinforcement in the slab is mandatory, using a bar in each rib of the profile. Using this solution, light slabs can be made, with a self-weight of less than 2 kN/m², through an agile and simple execution procedure.