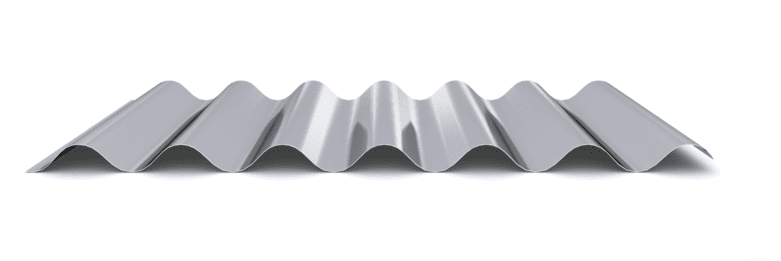

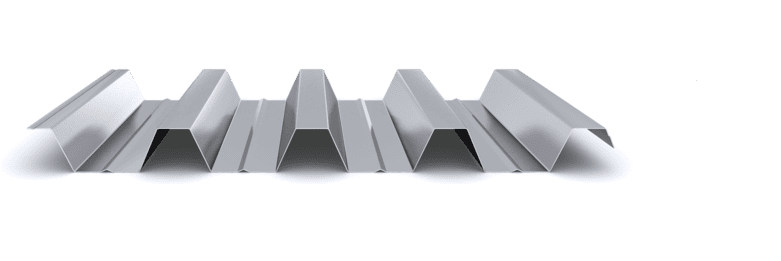

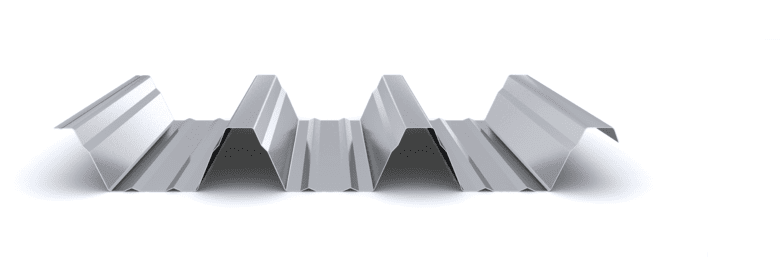

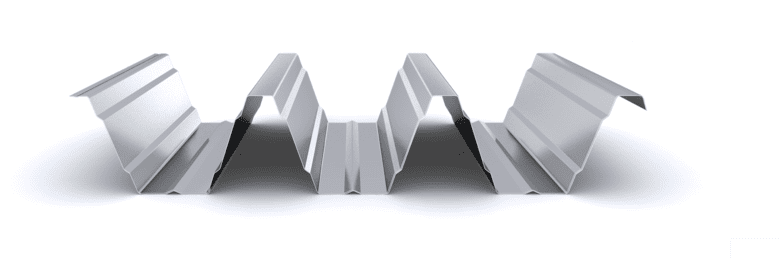

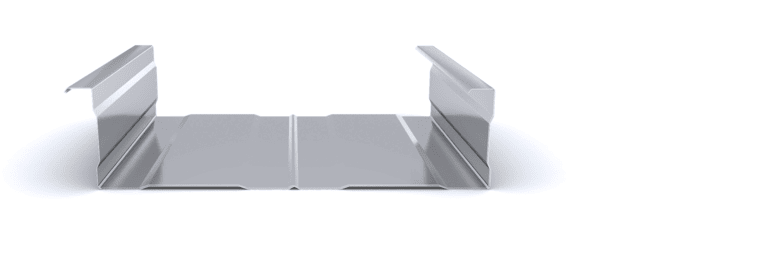

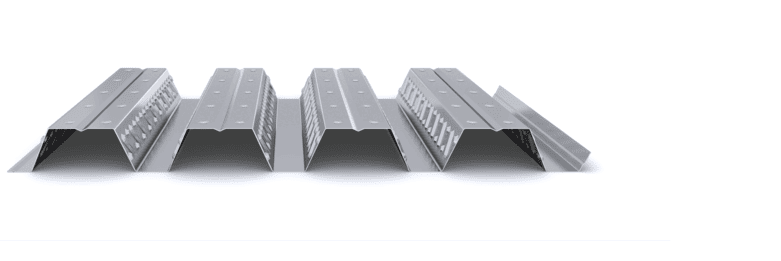

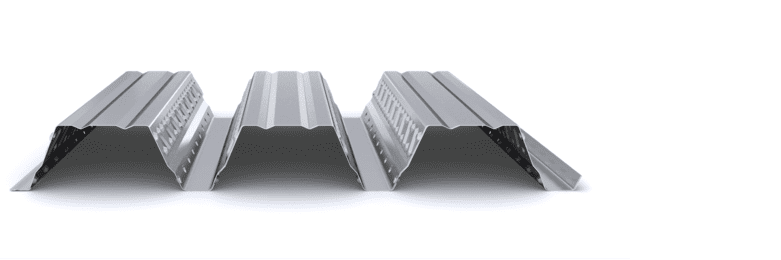

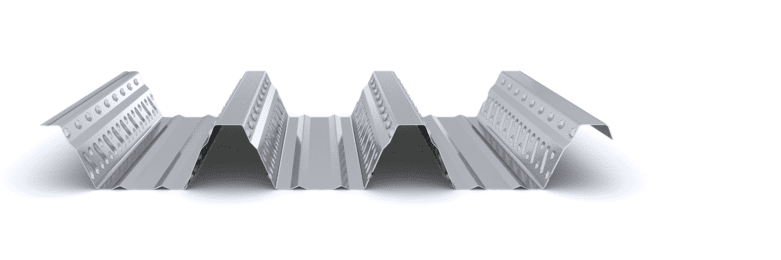

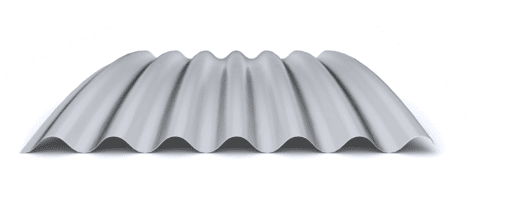

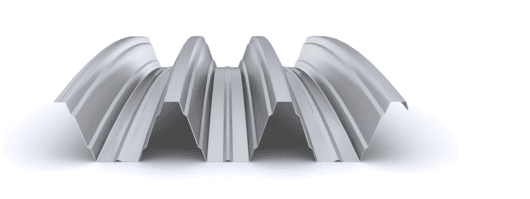

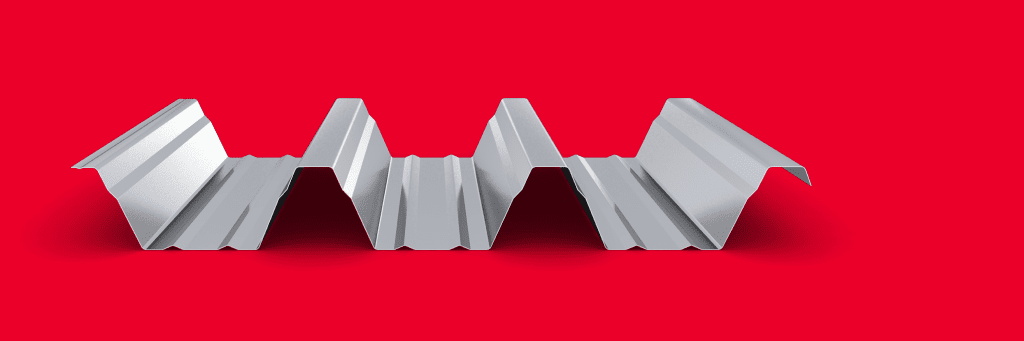

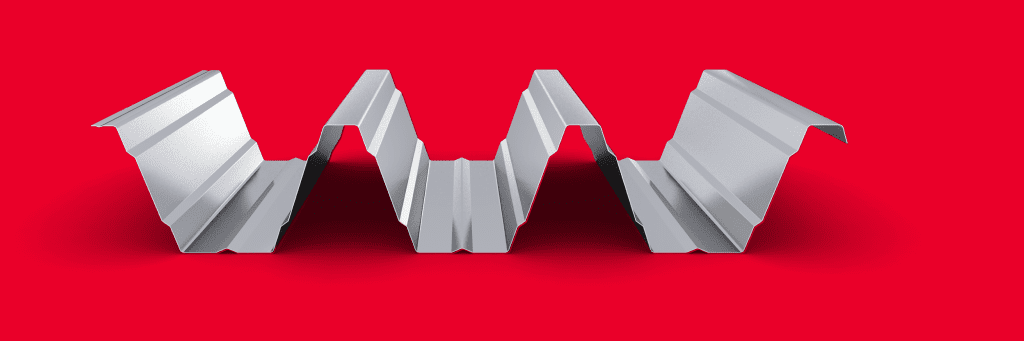

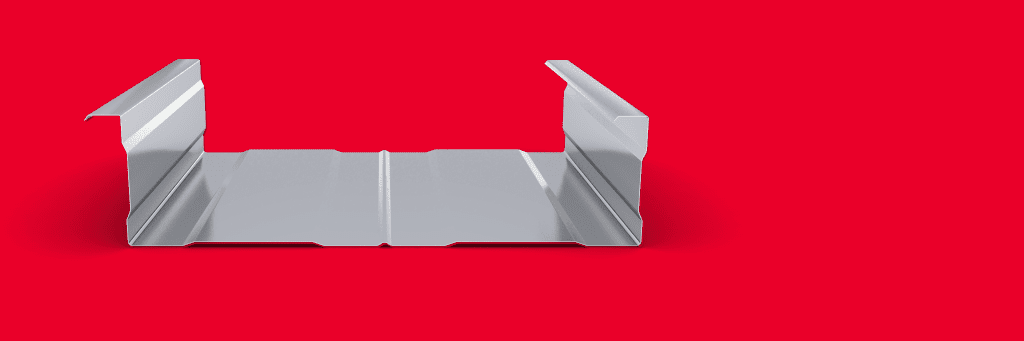

The industrial roof can be proposed using a simple solution, composed of a single corrugated profile, or a multi-layer, composed of a corrugated profile for the exterior roofing, a corrugated profile/inner tray and intermediate insulation.

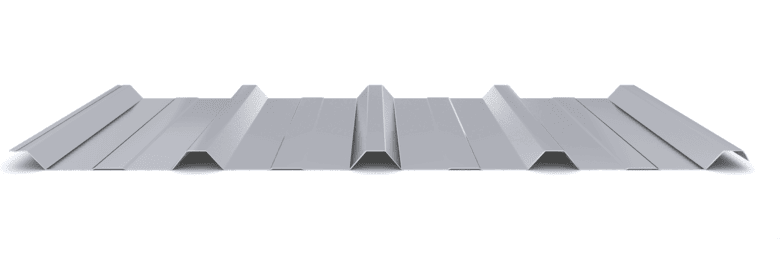

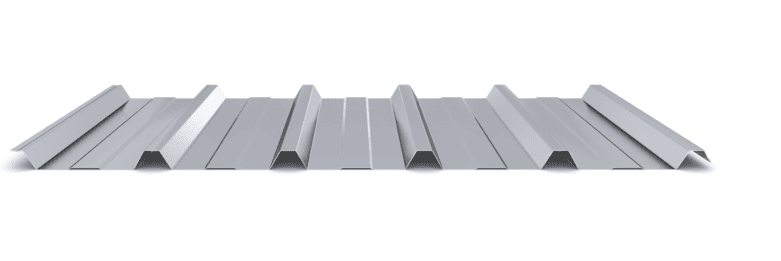

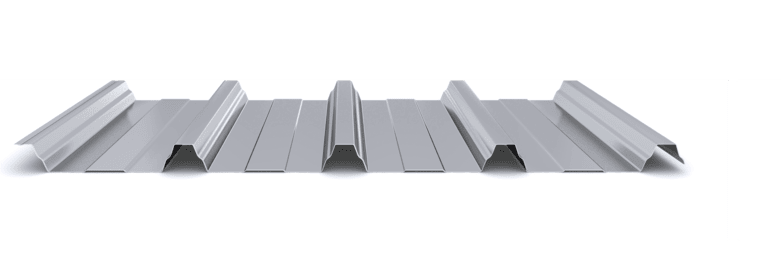

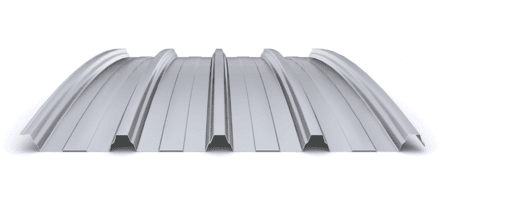

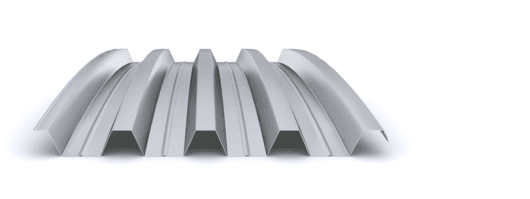

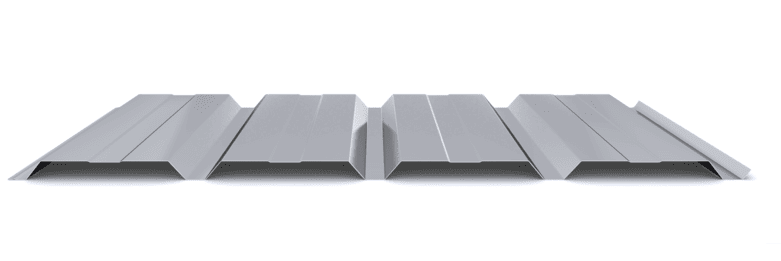

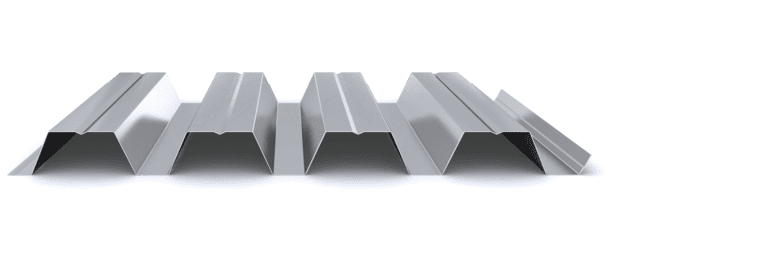

The simple industrial roof solution is made up of a trapezoidal profile that serves both as a sealing element and as support for the actions to which it is subjected. Its use is limited to canopies or closed spaces that do not require thermal and acoustic conditioning.

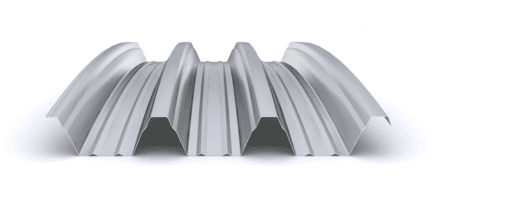

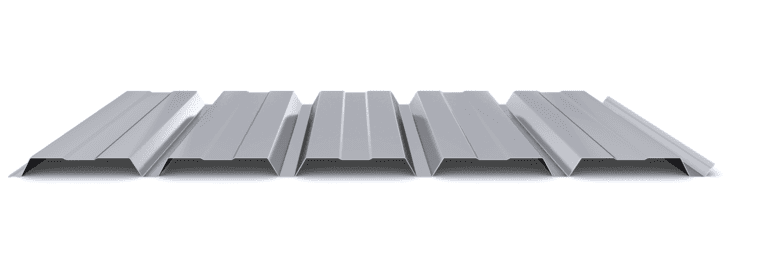

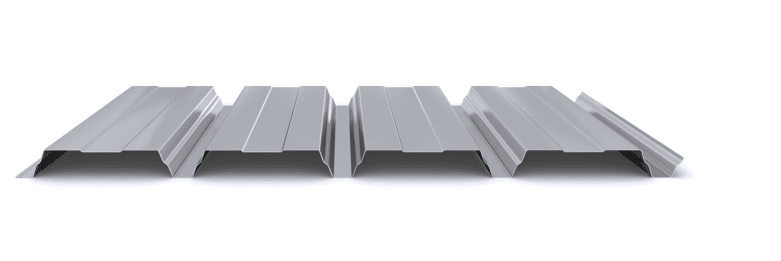

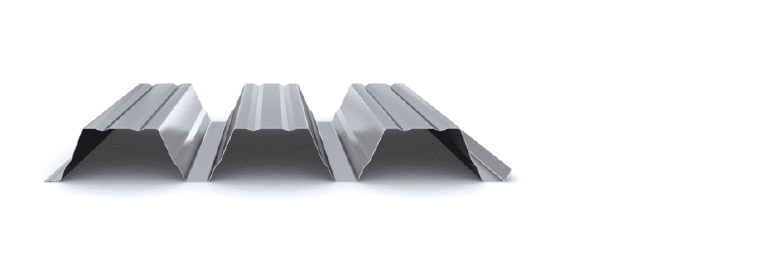

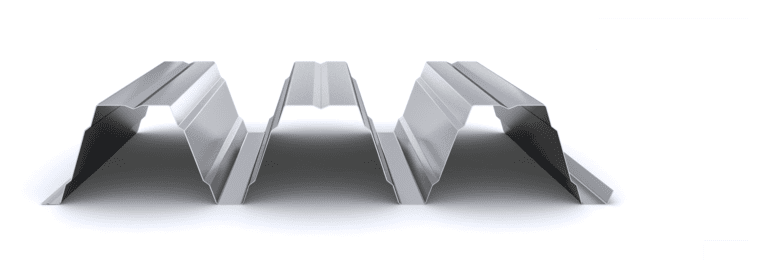

The multi-layer industrial roof solution is made up of a trapezoidal outer profile, which serves as a sealing element, and a corrugated profile/inner support tray, which performs the resistant function against external actions and the self-weight of the rest. of roof components: vapor barrier, thermal-acoustic insulation, separator profile and trapezoidal inner profile. This solution is used in closed spaces with thermal and acoustic conditioning needs.

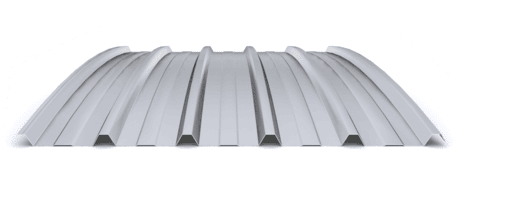

These solutions allow the construction of roofs with slopes between 5% and 10%, depending on the type of profile, with slopes greater than 10% being recommended.