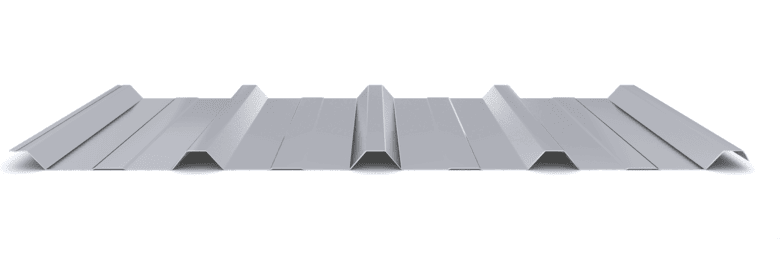

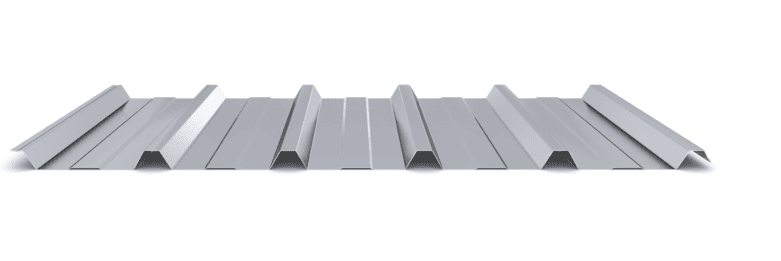

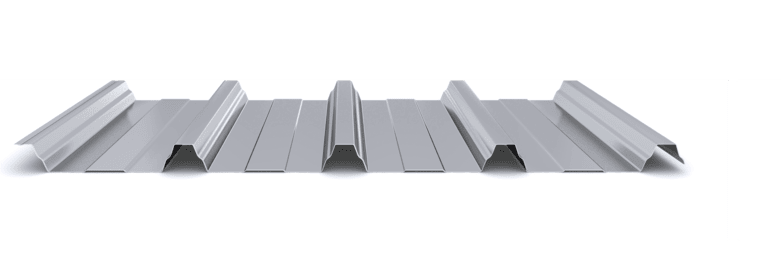

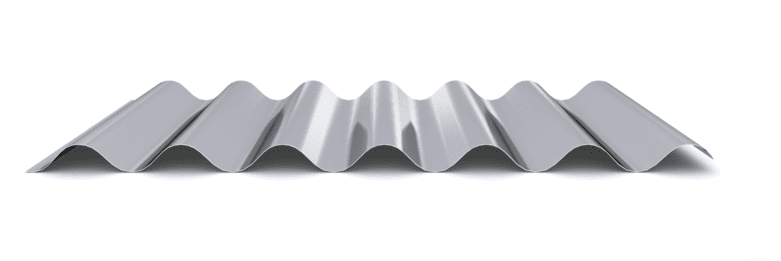

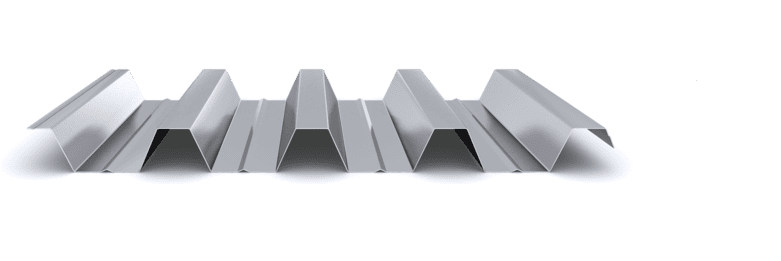

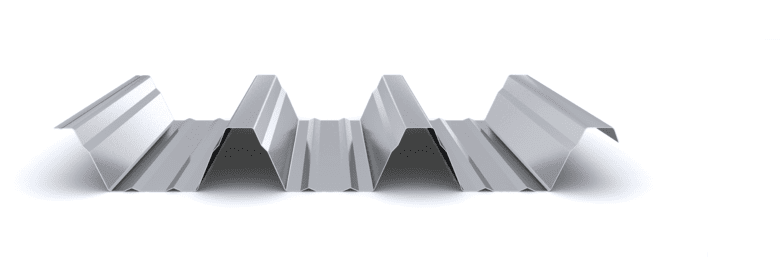

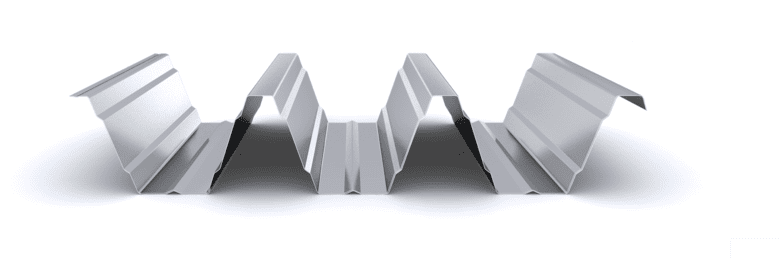

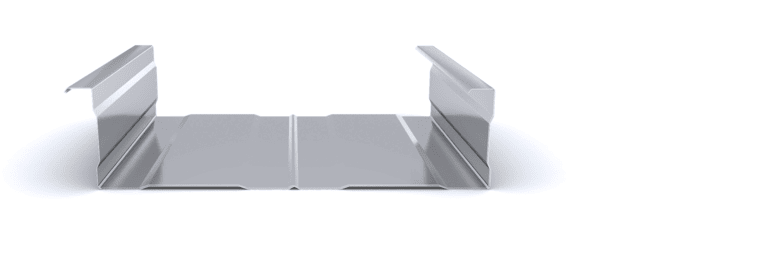

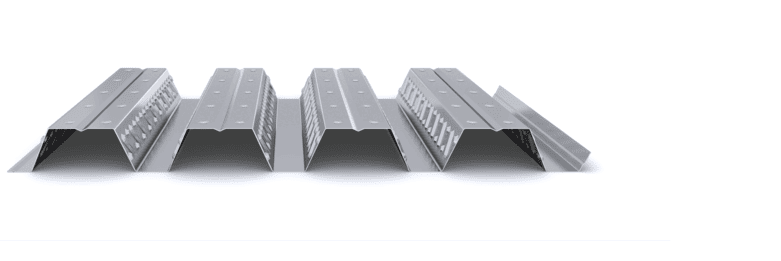

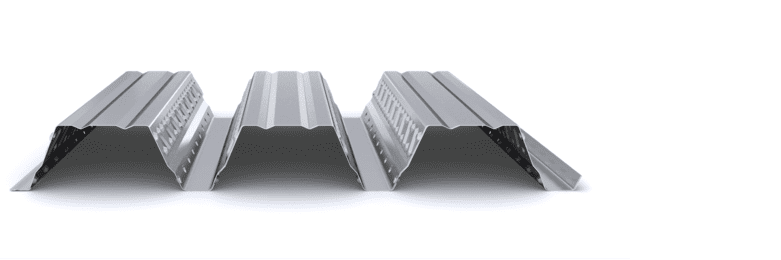

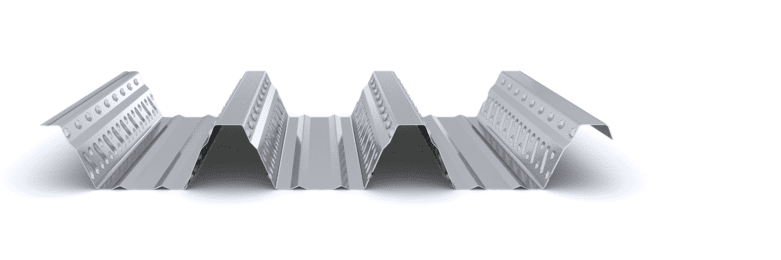

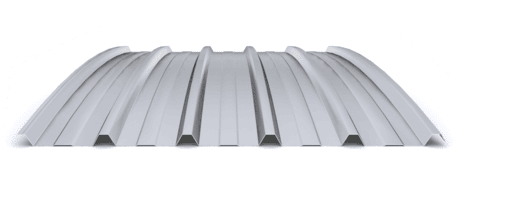

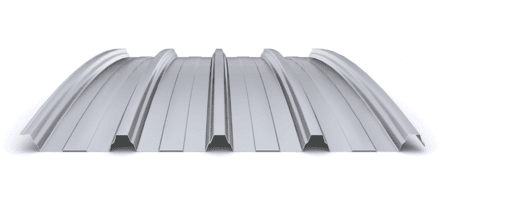

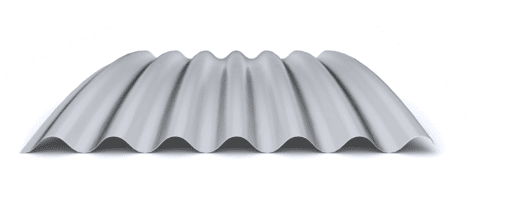

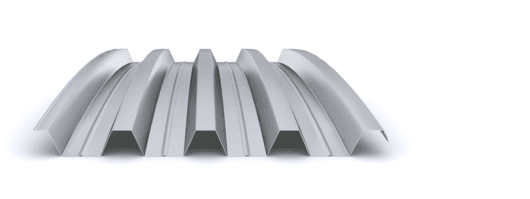

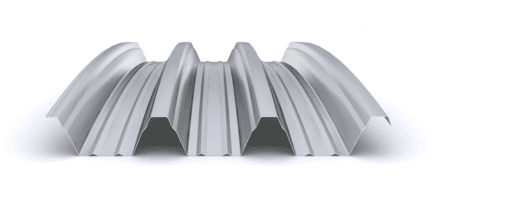

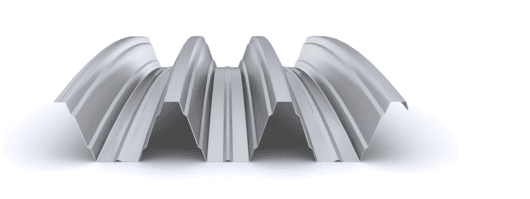

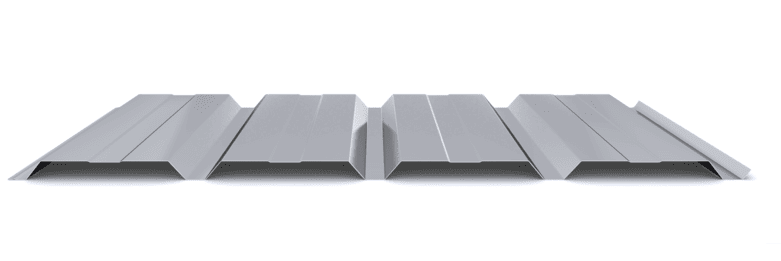

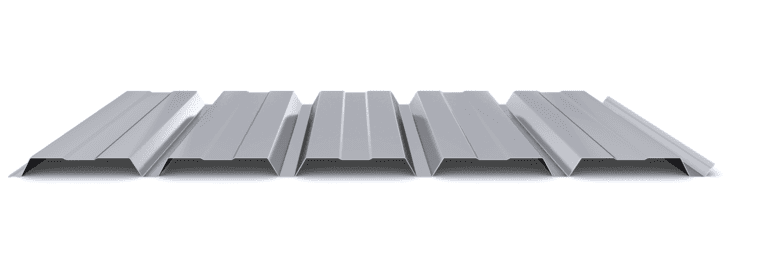

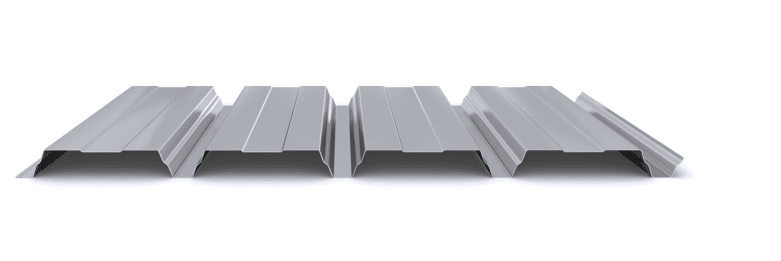

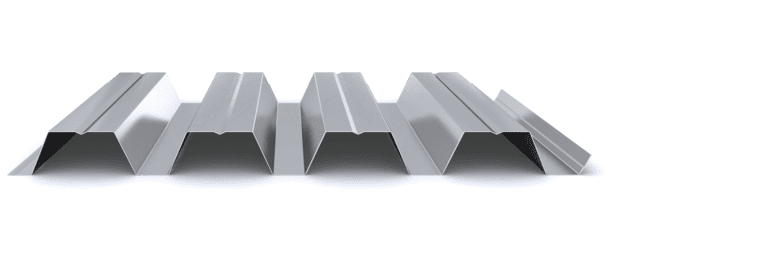

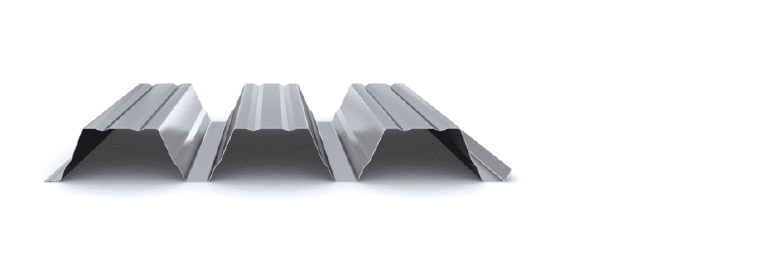

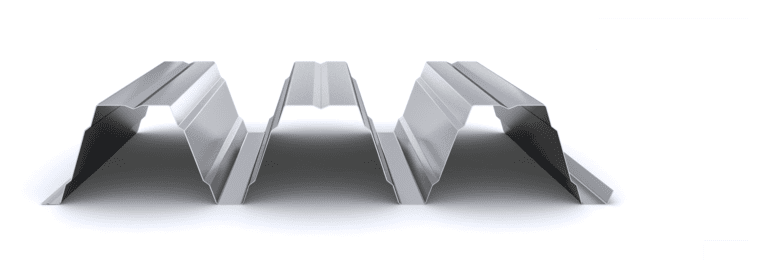

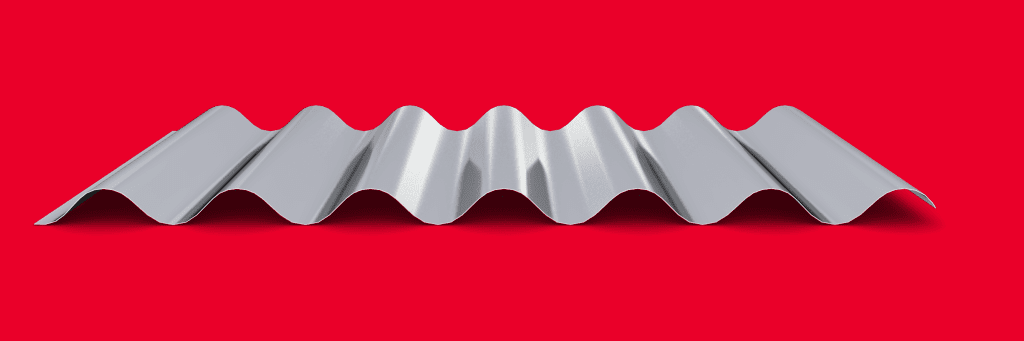

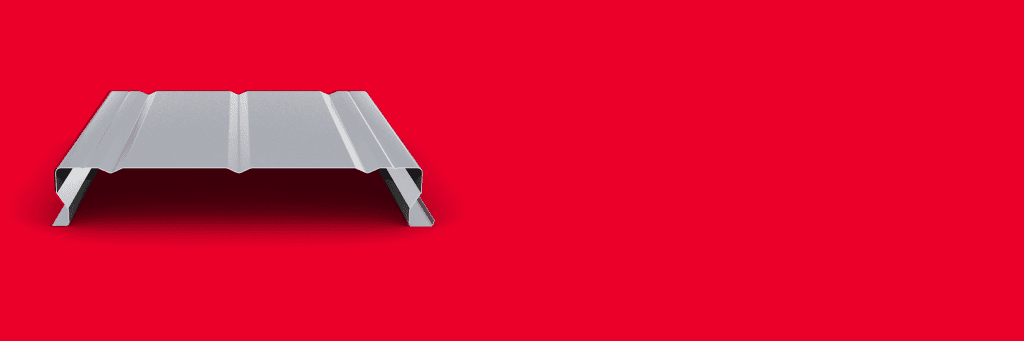

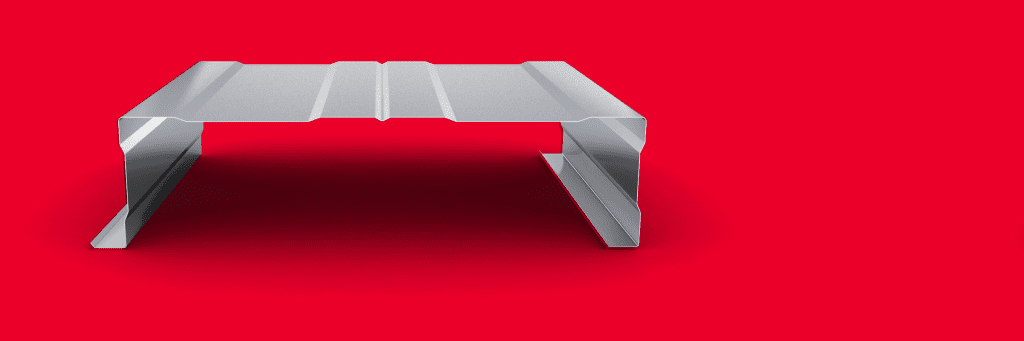

The industrial facade system can be proposed using a simple solution, composed of a single corrugated profile, or a multi-layer, composed of a corrugated profile for external cladding, a corrugated profile/inner tray and intermediate insulation.

The simple industrial facade solution is made up of a exterior facade profile that serves both as a sealing element and as support for the actions to which it is subjected. Its use is limited to canopies or closed spaces that do not require thermal and acoustic conditioning.

The multi-layer industrial facade solution is made up of a corrugated profile for external cladding, which serves as a sealing element, and a corrugated profile/inner support tray, which performs the resistant function against wind actions. This solution is used in closed spaces with thermal and acoustic conditioning needs.