STEEL FOR CONSTRUCTION

Guaranteed resistance and durability

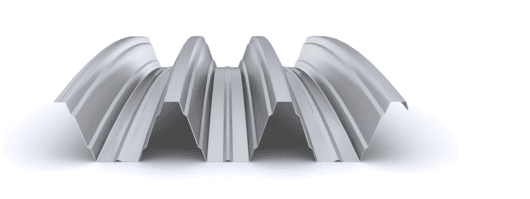

Steel is the most commonly used material in the manufacture of industrial enclosure profiles due to its mechanical properties and excellent formability. The application of zinc coatings and paint considerably improves its corrosion resistance. Other materials, such as Corten steel and aluminum, can also be used in the profiling process. Additionally, the perforated finish can be applied to any of these materials.

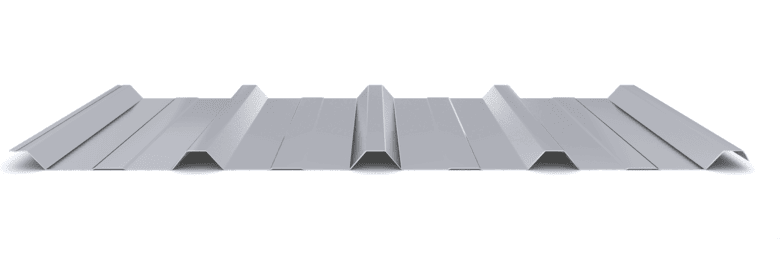

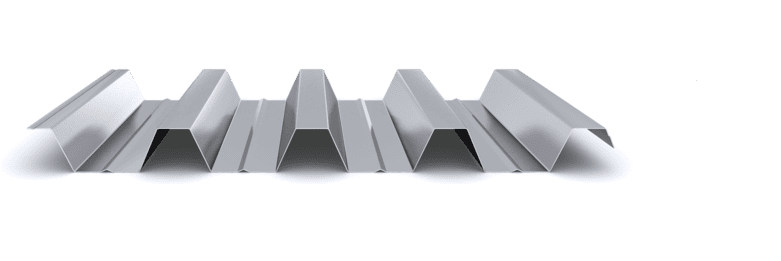

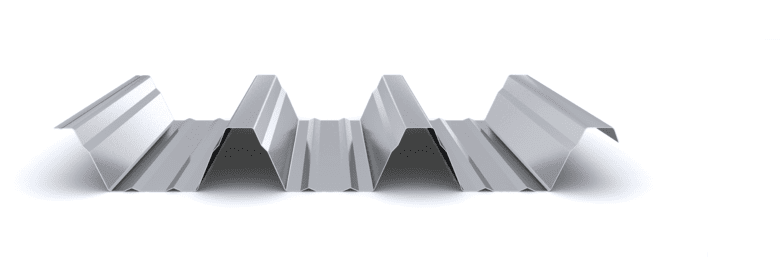

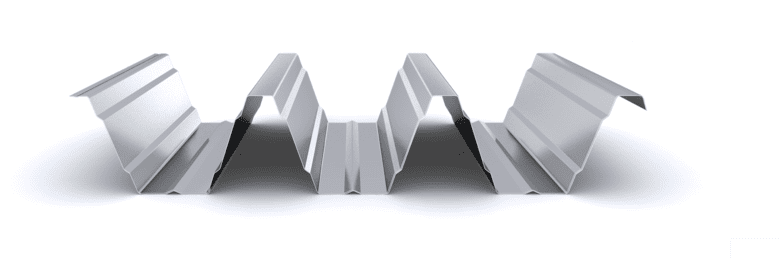

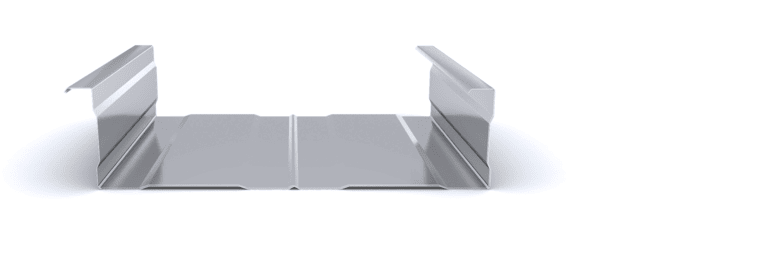

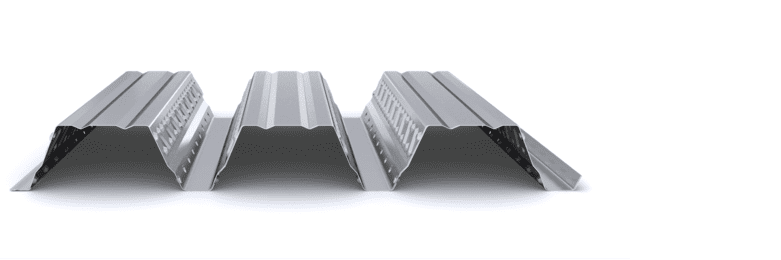

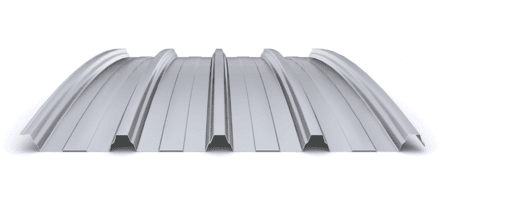

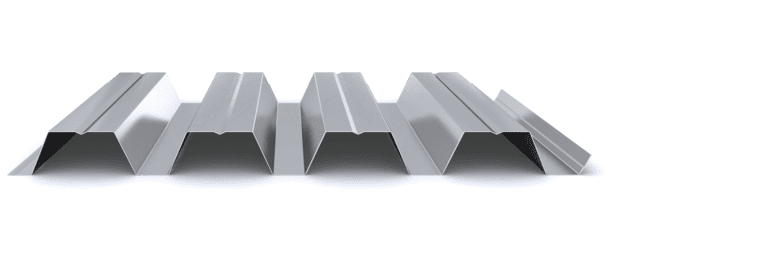

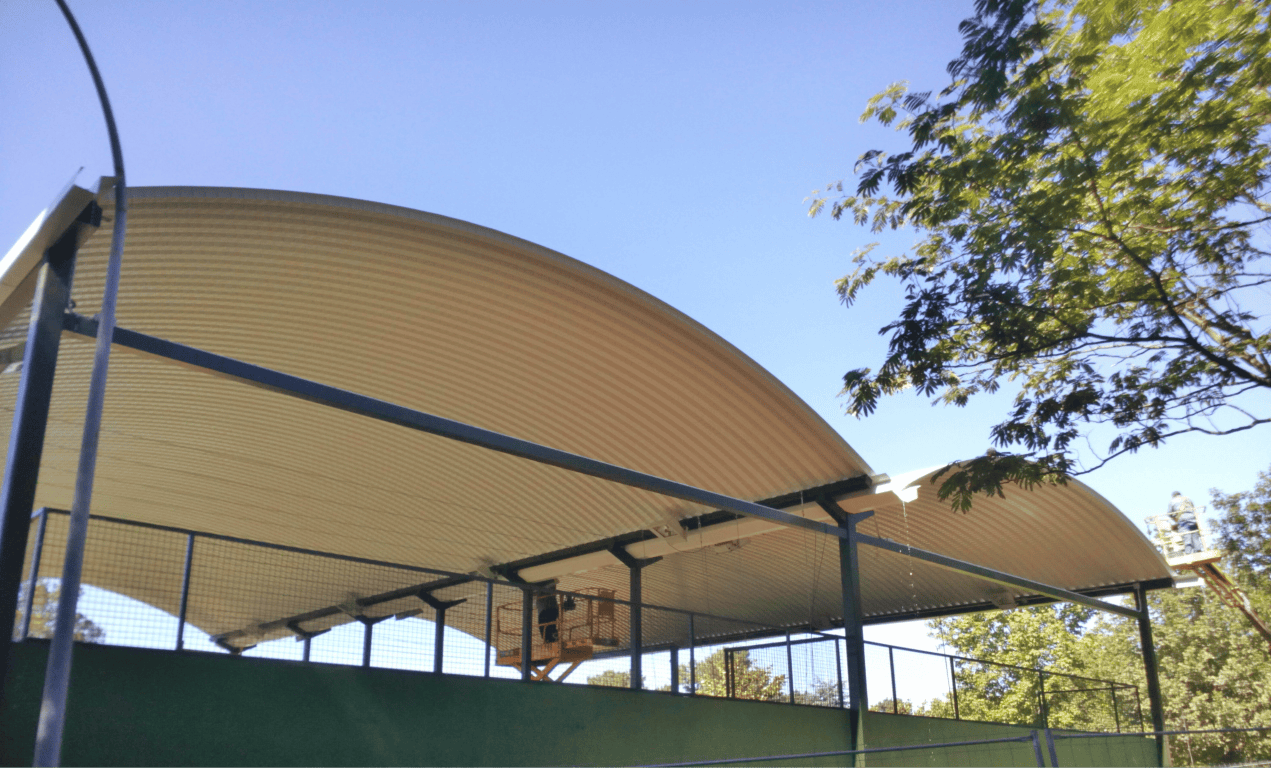

Steel

Steel for construction has significant advantages over other materials, such as resistance, lightness and durability, as long as adequate protection is guaranteed by a metallic zinc coating and a layer of paint to considerably improve its resistance to corrosion in environments. aggressive.

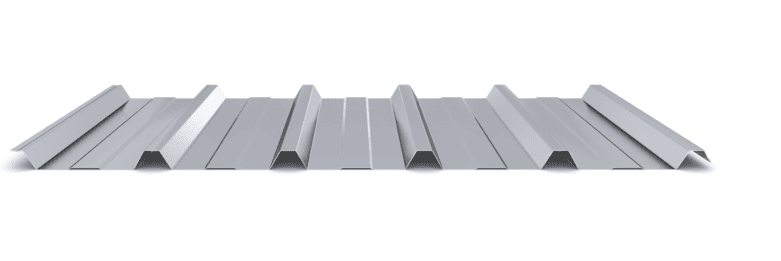

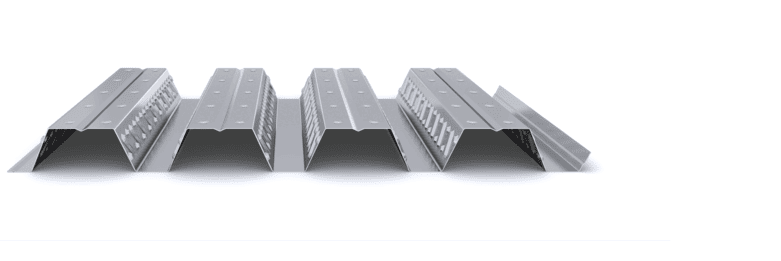

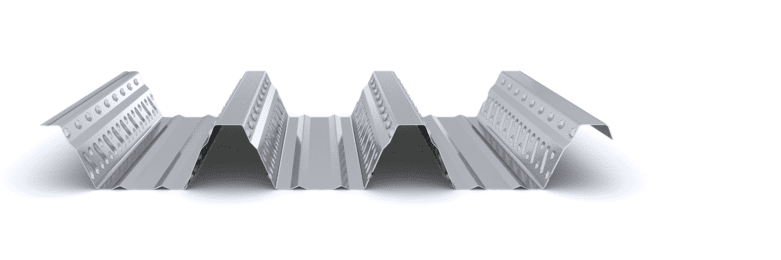

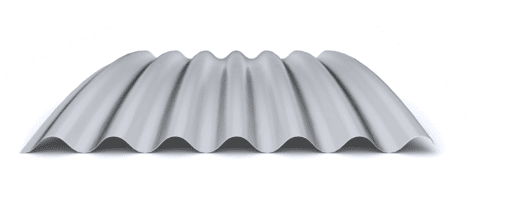

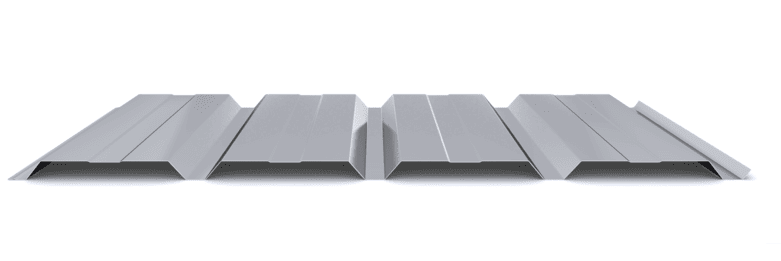

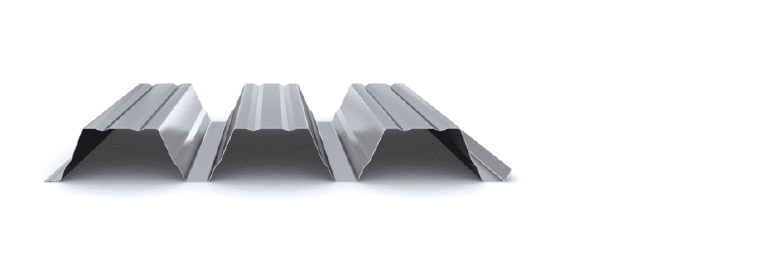

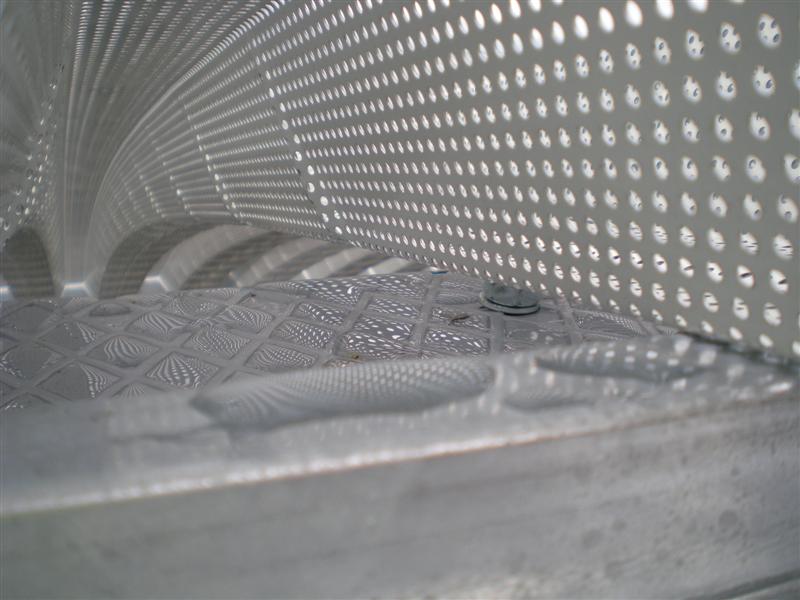

Perforated

The perforated finish consists of perforating the material before being shaped, mainly in interior applications to improve acoustic absorption or outdoors to act as solar control.

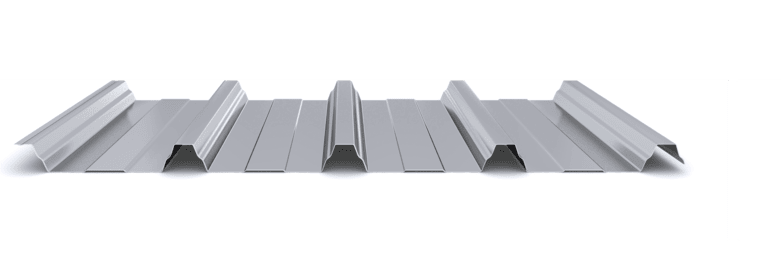

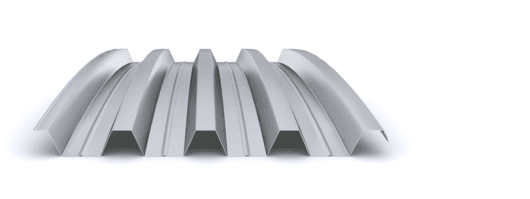

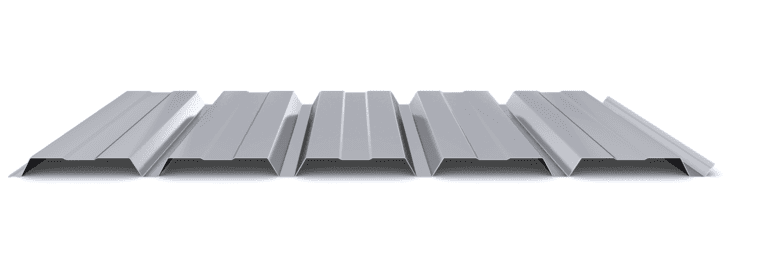

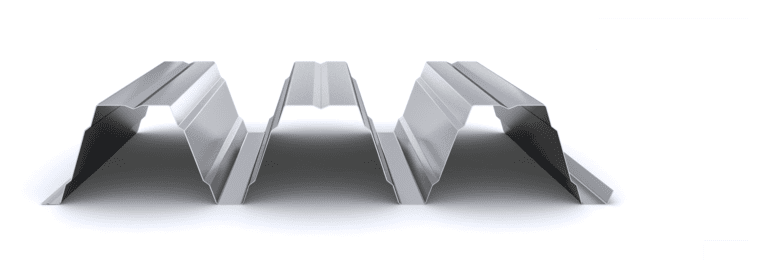

Corten steel

Corten steel stands out for its resistance to atmospheric corrosion and its characteristic appearance, thanks to a protective oxide layer formed by its copper and chromium alloy, being ideal for facade applications with minimal maintenance.

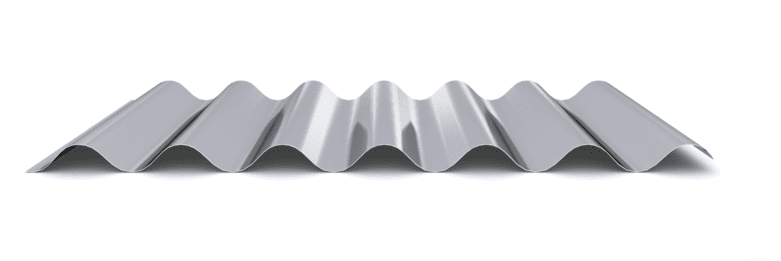

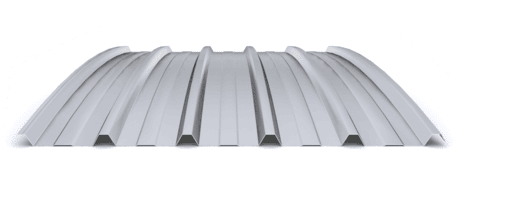

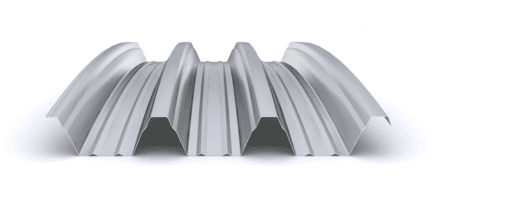

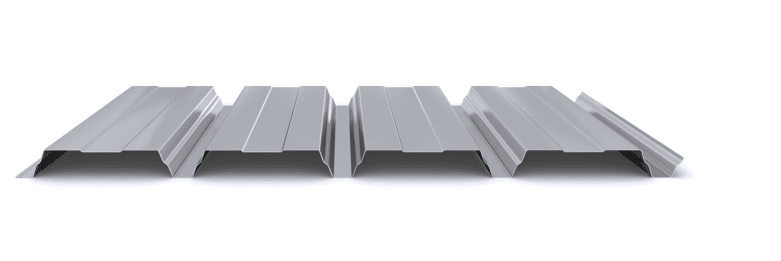

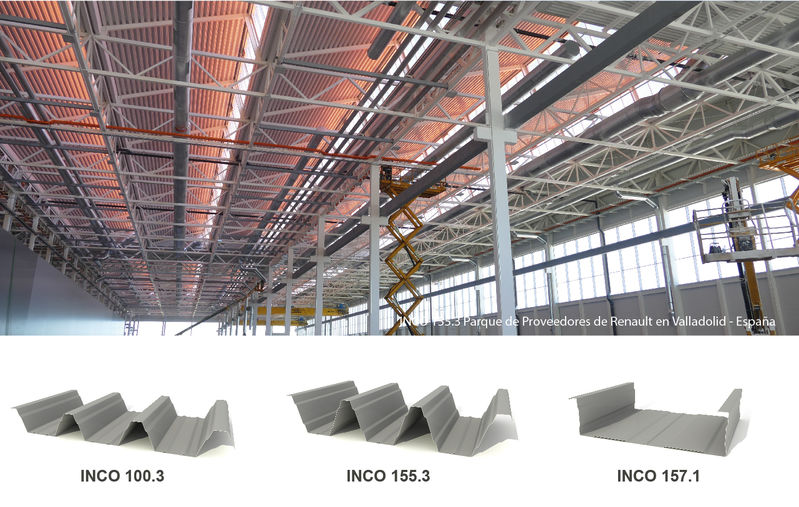

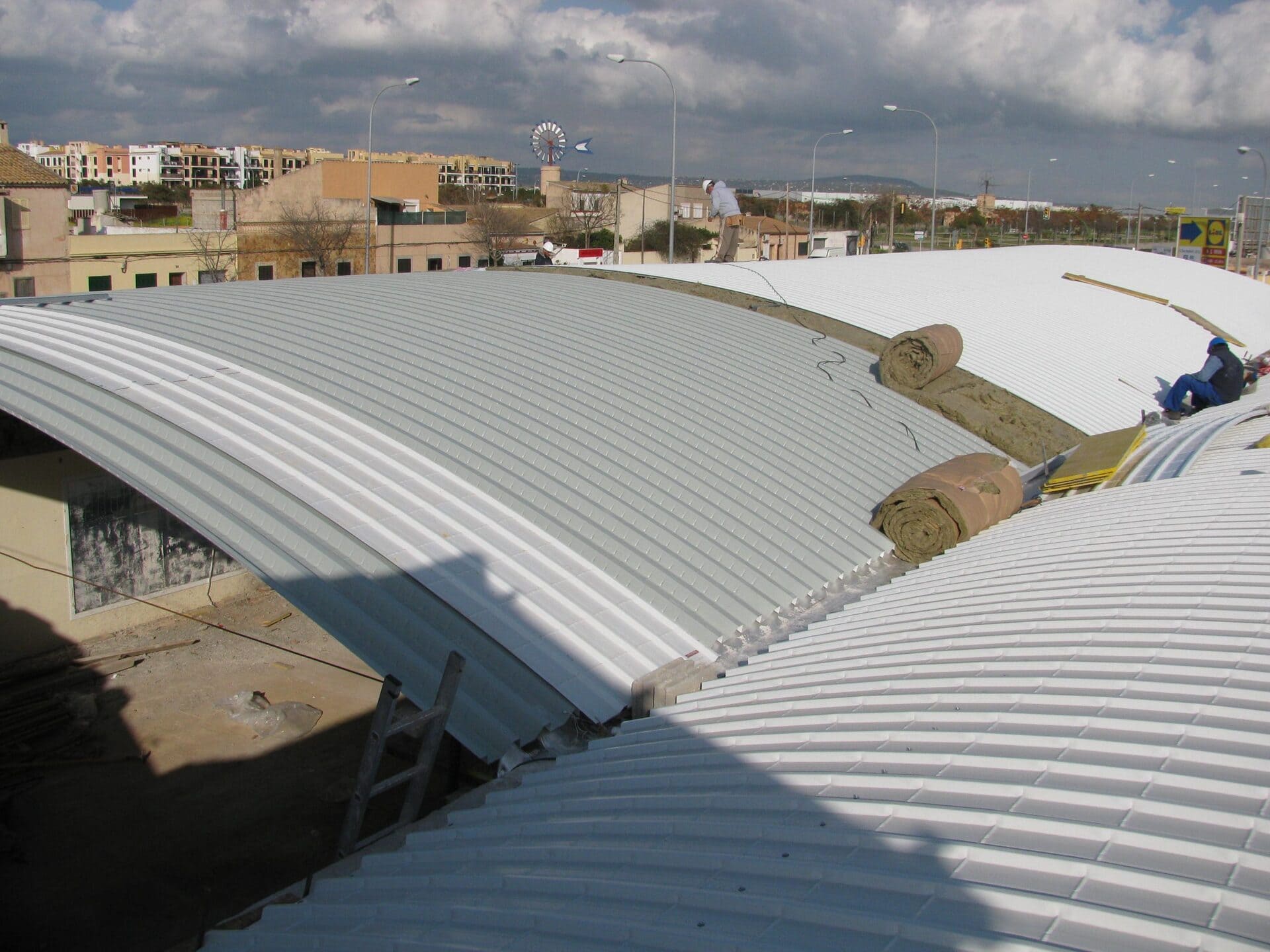

Aluminium

Aluminum is a material widely used in construction due to its strength, durability, low weight and finish. At Incoperfil, we have acquired experience in the manufacture of corrugated aluminum profiles for application in industrial enclosures, offering high quality products.