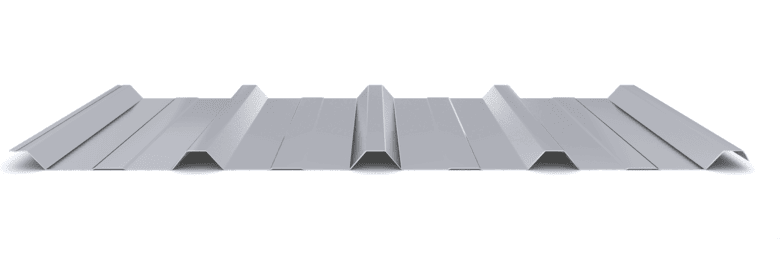

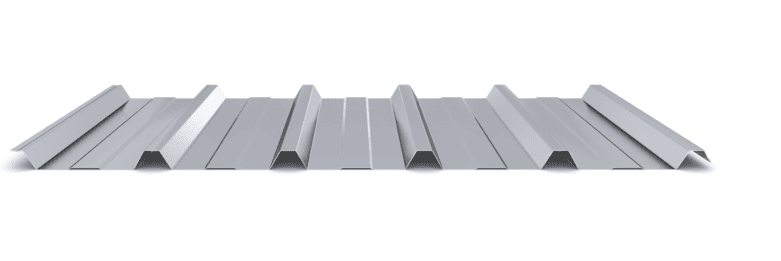

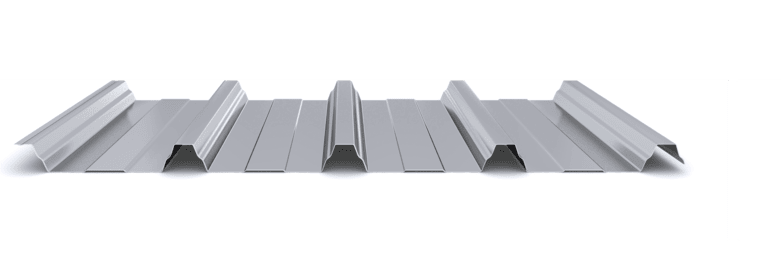

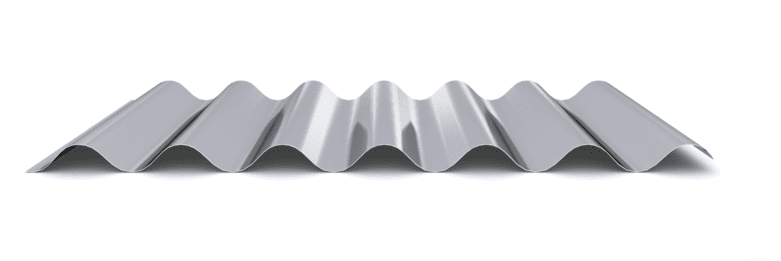

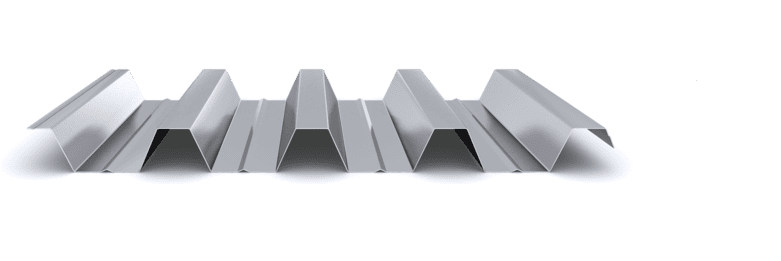

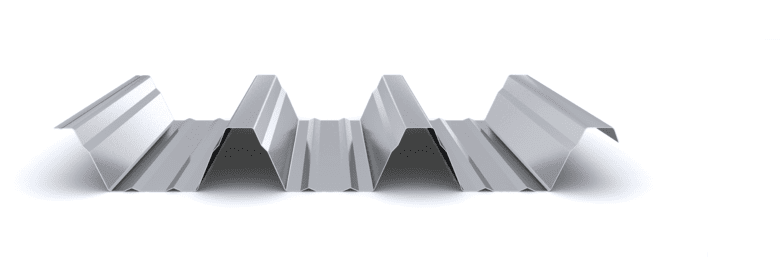

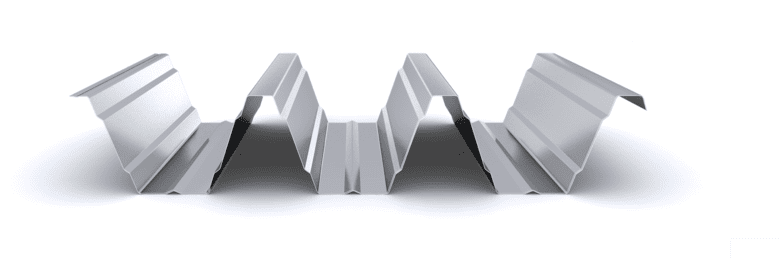

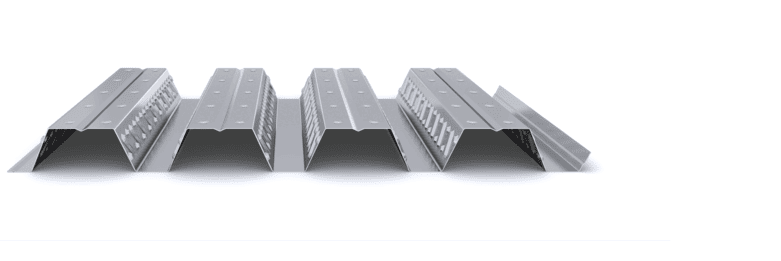

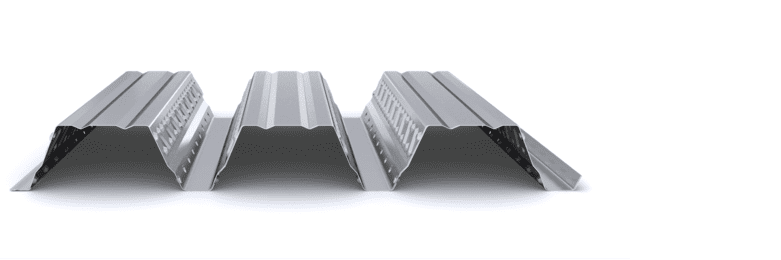

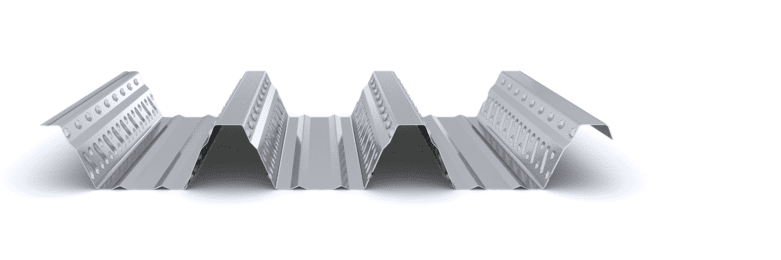

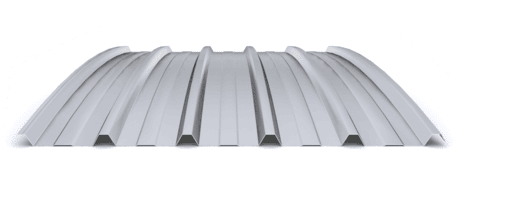

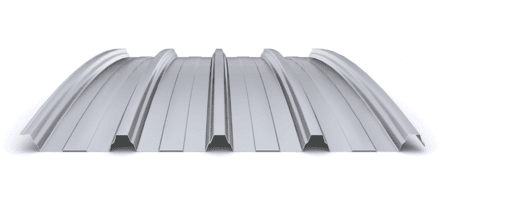

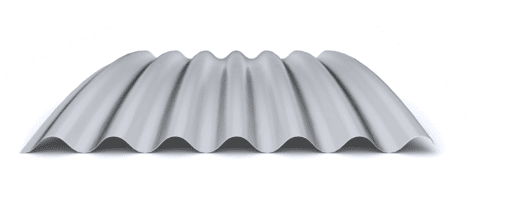

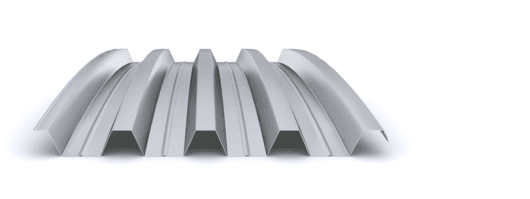

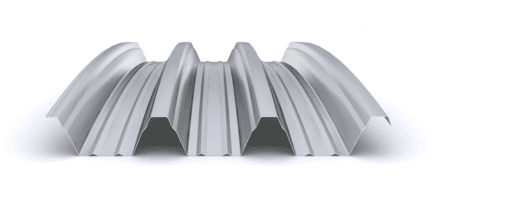

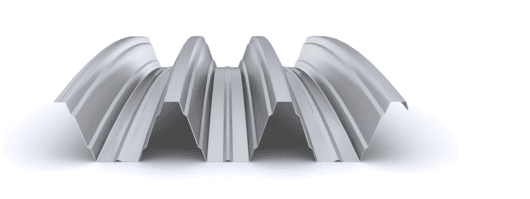

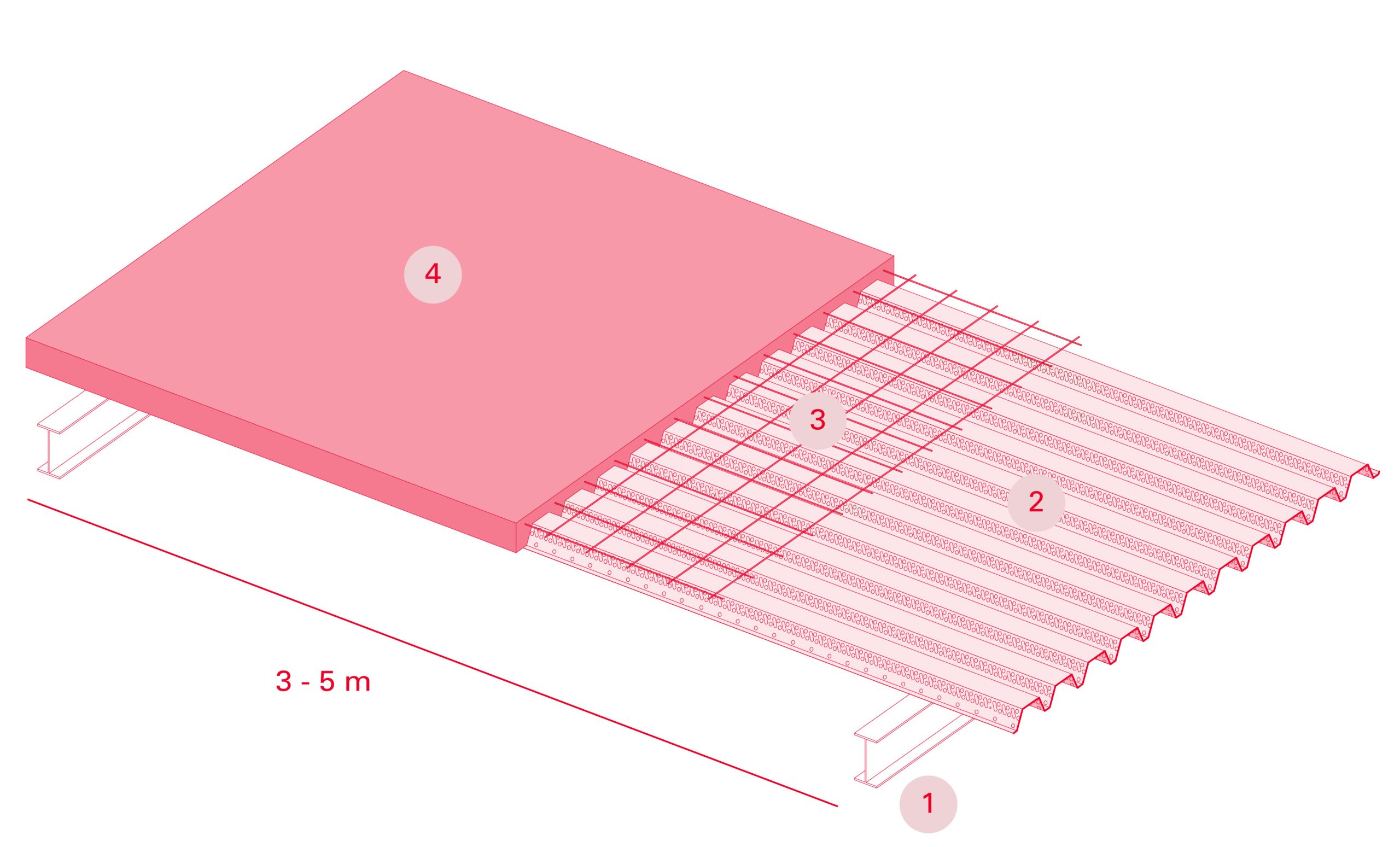

The composite floor profile is a structural element used in the construction sector for the execution of composite slabs.

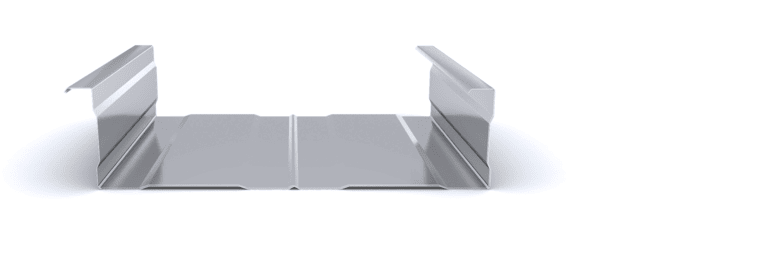

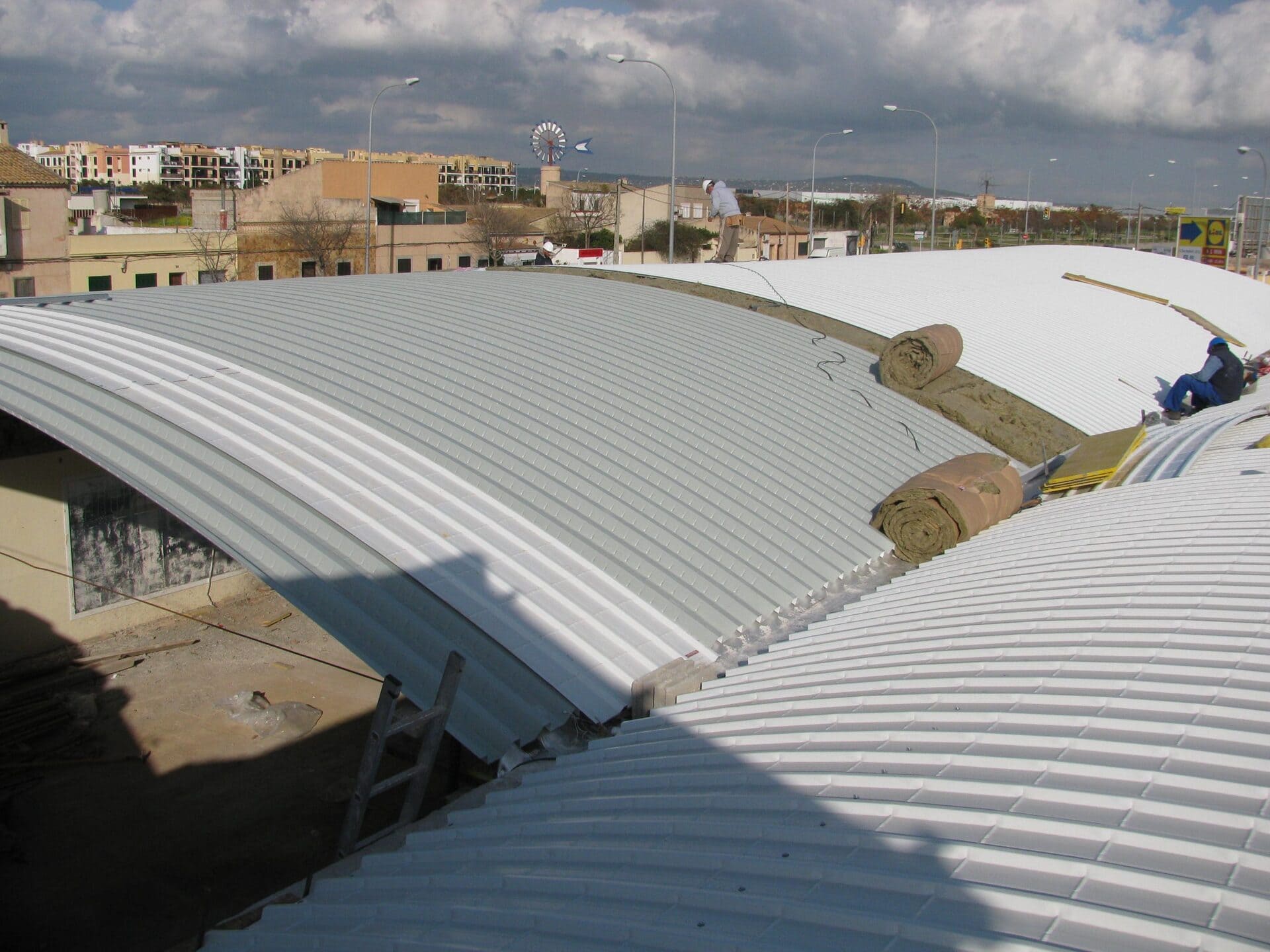

The composite slab system consists of a corrugated galvanized steel profile that serves as a formwork for a cast-in-situ concrete slab. Once the concrete has reached the characteristic strength required by the project, the corrugated profile and the concrete slab work together.

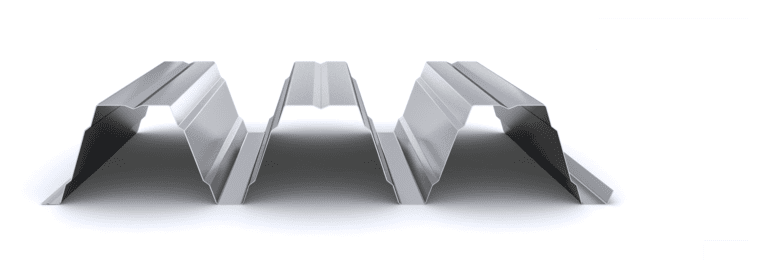

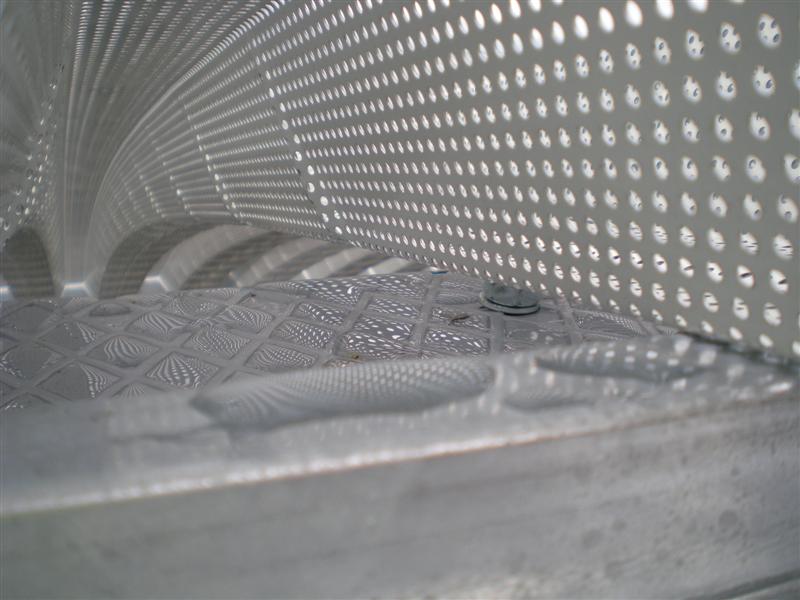

Its design incorporates embossments that improve bonding with the concrete, optimizing the overall structural behavior.

This construction system is widely used in industrial, commercial, and residential buildings due to its ability to reduce execution time and minimize the need for additional shoring on site.

Let’s take a look at more aspects of the composite floor profile below.

How the composite floor profile works

The operation of the composite floor profile is based on the combination of two materials with complementary properties: galvanized steel and structural concrete.

The interaction between the two results in improved load capacity and efficient distribution of forces.

Operating Phases:

- Before Concrete Hardening

- The sheet supports the execution loads, its own weight, and the weight of fresh concrete.

- It does not require traditional formwork, which speeds up construction.

- It serves as a safe working platform for workers.

2. After Concrete Hardening

- The sheet and concrete act together as a composite slab.

- The embossments on the sheet prevent slippage and improve adhesion with the concrete.

- Load distribution is optimized, reducing the need for heavy structural sections.

How much weight can a composite floor profile?

The load capacity of a composite floor profile depends on several factors:

- Sheet thickness (usually between 0.75 mm and 1.2 mm).

- Profile height (the higher it is, the greater the load capacity).

- Type and strength of the concrete used.

- Clear span between supports.

- Presence or absence of shear connectors.

Manufacturers of composite floor profiles, such as Incoperfil, provide load tables and technical datasheets detailing the structural capacity based on design conditions.

Generally, a composite slab with a composite floor profile can support usage loads in commercial and industrial buildings without the need for additional reinforcements, as long as the design criteria established by current regulations are followed.

When is it used?

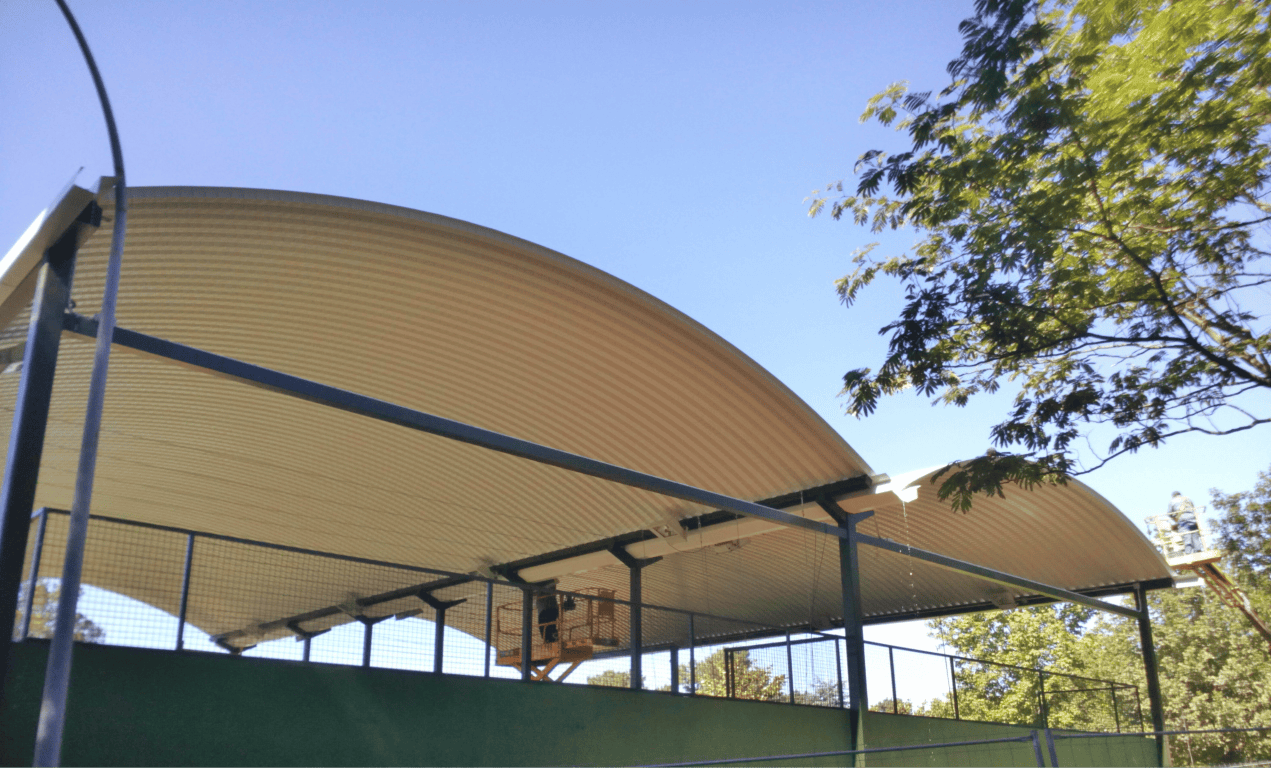

The use of composite floor profiles is indicated in various types of construction where a lightweight and fast-execution slab solution is required.

Some of the most common cases include:

- Industrial and logistical warehouses: Enables the execution of slabs over metal structures without the need for traditional formwork.

- Office and commercial buildings: Facilitates the construction of intermediate slabs with reduced construction times.

- Residential buildings and homes: Used in renovations and extensions where reducing structural weight is a key factor.

- Parking and modular structures: Its quick installation makes it ideal for projects with tight deadlines.

In these cases, the composite floor profile allows for the reduction of costs associated with labor and auxiliary materials, improving the efficiency of project execution.

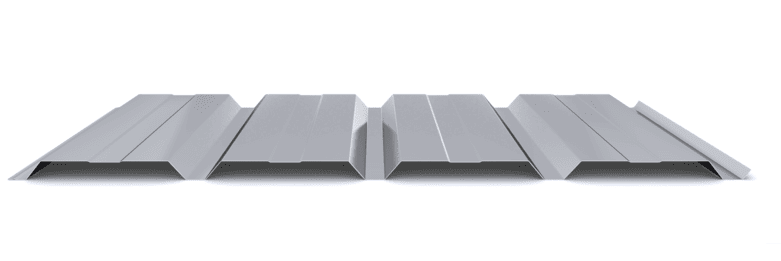

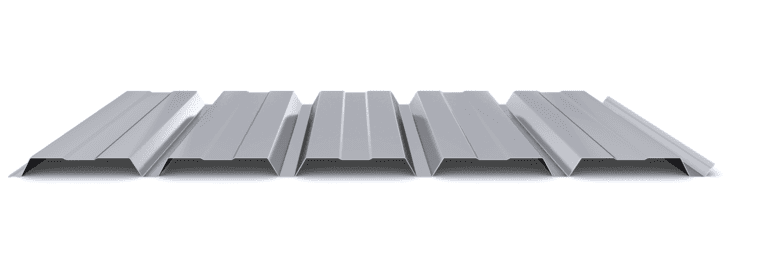

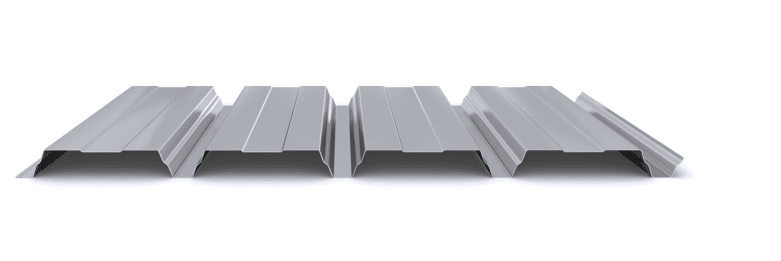

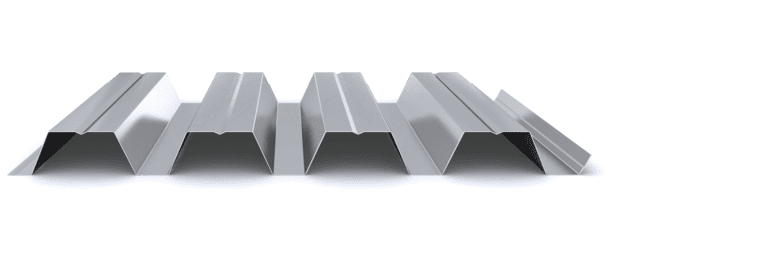

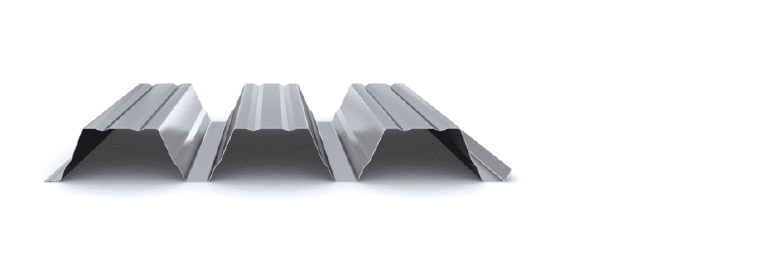

Composite floor profile Measurements

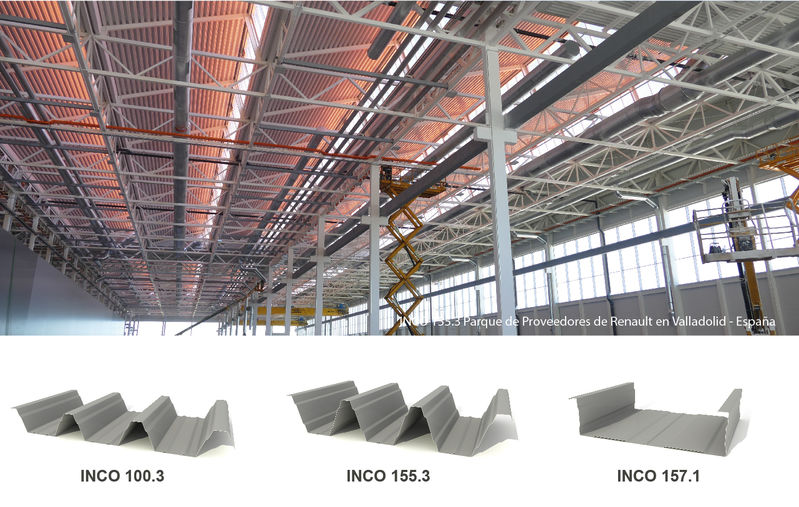

The measurements of the composite floor profile vary depending on the model and the manufacturer.

However, there are standard dimensions available on the market that ensure proper integration with composite slab systems.

Main Parameters:

- Sheet thickness:

- 0.75 mm

- 1.0 mm

- 1.2 mm

- Profile height:

- 70 mm

- 100 mm

- Useful width:

- 840 mm

- 825 mm

- Customizable lengths:

- Manufactured in lengths tailored to each project, optimizing material use and minimizing waste

As you can see, the composite floor profile is a key element in the design of composite slabs, allowing for efficient and safe construction in industrial, commercial, and residential building projects.

Its integration with the collaborative slab optimizes structural behavior, facilitates execution, and reduces costs.

At Incoperfil, we offer composite floor profiles solutions for slabs tailored to the technical requirements of each project, complying with current regulations and guaranteeing the highest quality in our products.