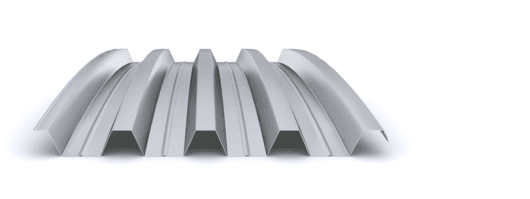

Trimming

The different finishing encounters are resolved using longitudinal pieces of sheet metal, formed by folding. These finishing pieces will adjust to the characteristics of each meeting and roof solution and, therefore, their dimensions will have to be defined for each project. They are available in both galvanized steel and the different colors of pre-lacquered galvanized steel, and in thicknesses from 0.60 mm to 1.20 mm.

The most common auction matches are:

- Ridge cap trim uitable for the closuring of the upper encounter between two upward slopes of roof.

- Side wall trim:Trim of encounter between the lateral upward slope of a roof and the vertical enclosure.

- Rake trim is the top closure of two vertical faces or between a vertical face and other elements such as roofings or drains.

- Base Flasing lower trim of façade and doors and windows header.

- Trim of closure between upward slope of the roof (the end of the slope) with vertical face.

- Rake trim is the top closure of two vertical faces or between a vertical face and other elements such as roofings or drains.

- Outside corner trim is suitable for the encounter solution between two vertical faces

- Inside corner trim suitable for resolving the solution to the encounter between two vertical faces.

- Expasion joint for facade: Trim of closure of the expansion joint of façade made up of one piece with a break shaped of a V.

- Sill trim: Metal trim for the windows. It is placed on the lower side of the window wich main function is to avoid rain water entry.

- Expansion joint for roofing: Trim of closure of the expansion joint in roofing, made up of two pieces with free flap joint.

- Deck roofing perimetral trim It is available in galvanized.

- Central gutter: Element suitable for collecting and channeling rainwater of just two slopes of the roof It is available in galvanized as well as in the different ranges of pre-lacquered colours.

- Valley cover trim: Trim with the function of blinding the valleys of the roof in case that exist hollows in the slope.

- End gutter: Element suitable for collecting and channeling rainwater of just one slope of the roof.

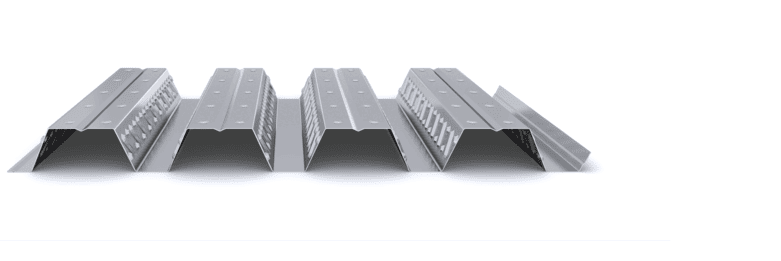

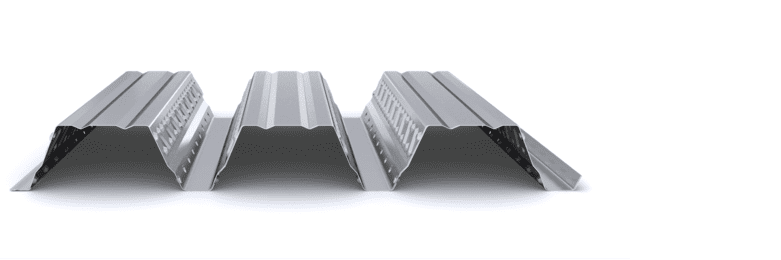

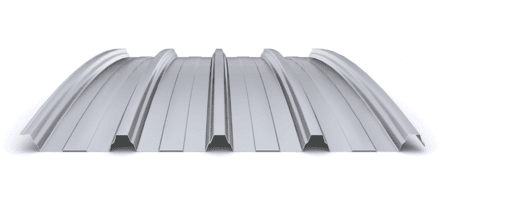

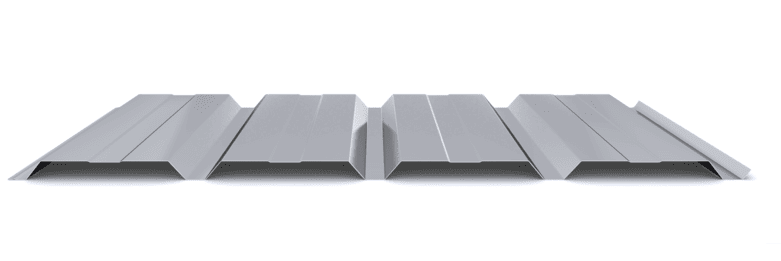

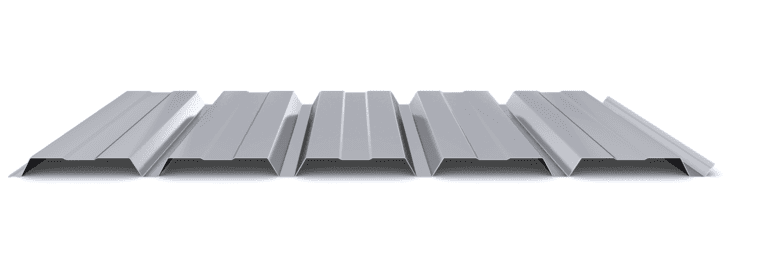

The different encounters of die-cut finishes are resolved using longitudinal pieces of sheet metal, formed by folding. These finishes have a cutout on the longitudinal edges, in the shape of the profile, to allow them to fit together and improve water and dust tightness.

These finishing pieces will adjust to the characteristics of each meeting and roof solution and, therefore, their dimensions will have to be defined for each project. They are available in both galvanized steel and the different colors of pre-lacquered galvanized steel, and in thicknesses from 0,60 mm to 1,20 mm.

The most common die-cut finishing encounters are:

- Die-cut ridge cap to close the upper junction between two roof skirts.

- Die-cut side wall trim to close the meeting between the roof skirt and the vertical façade enclosure.

- Die-cut rake trim to close the meeting between the vertical wall with a high slope.

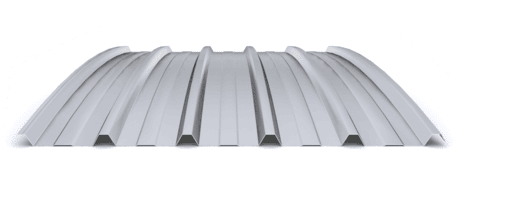

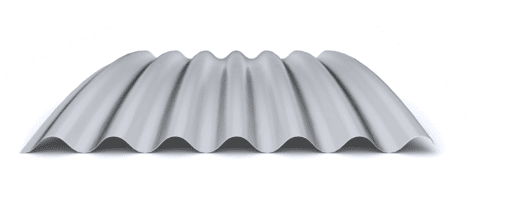

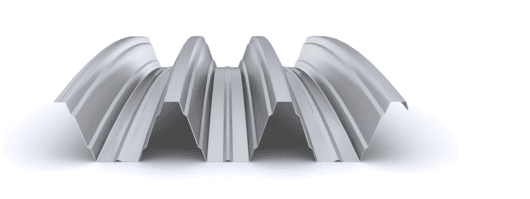

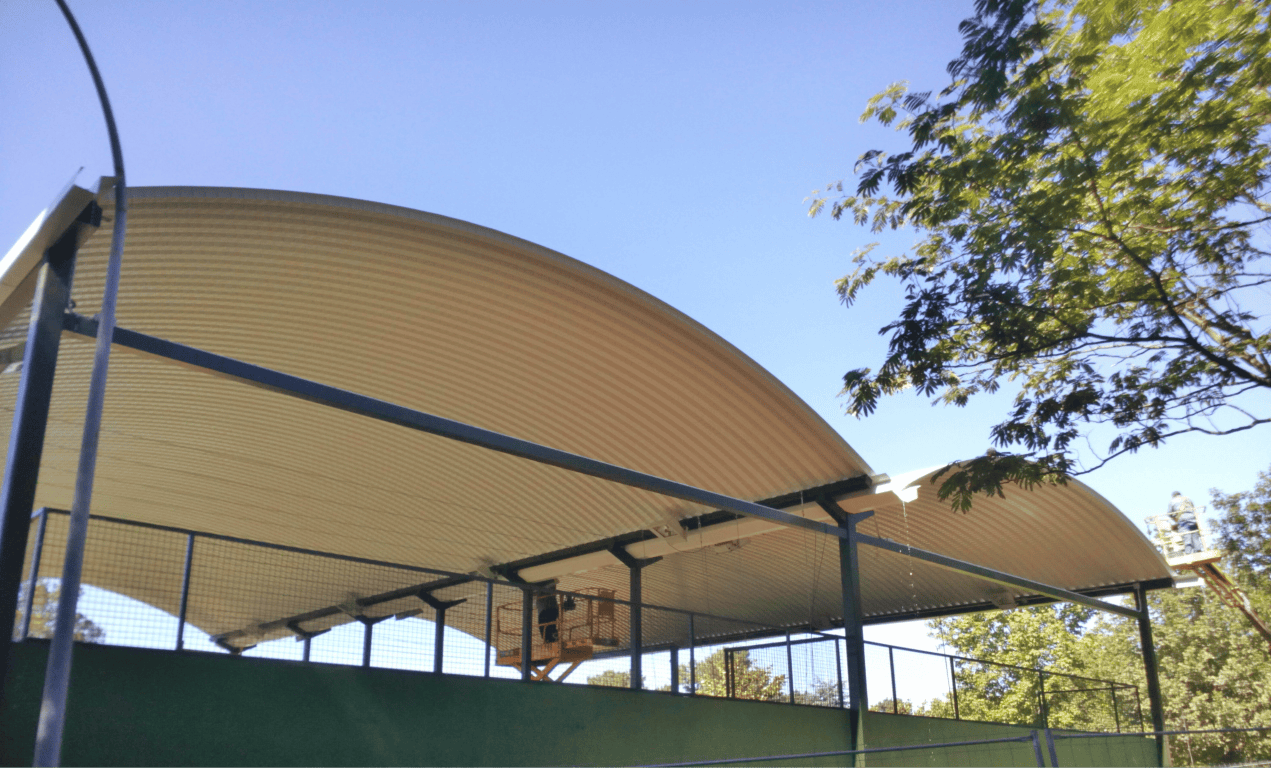

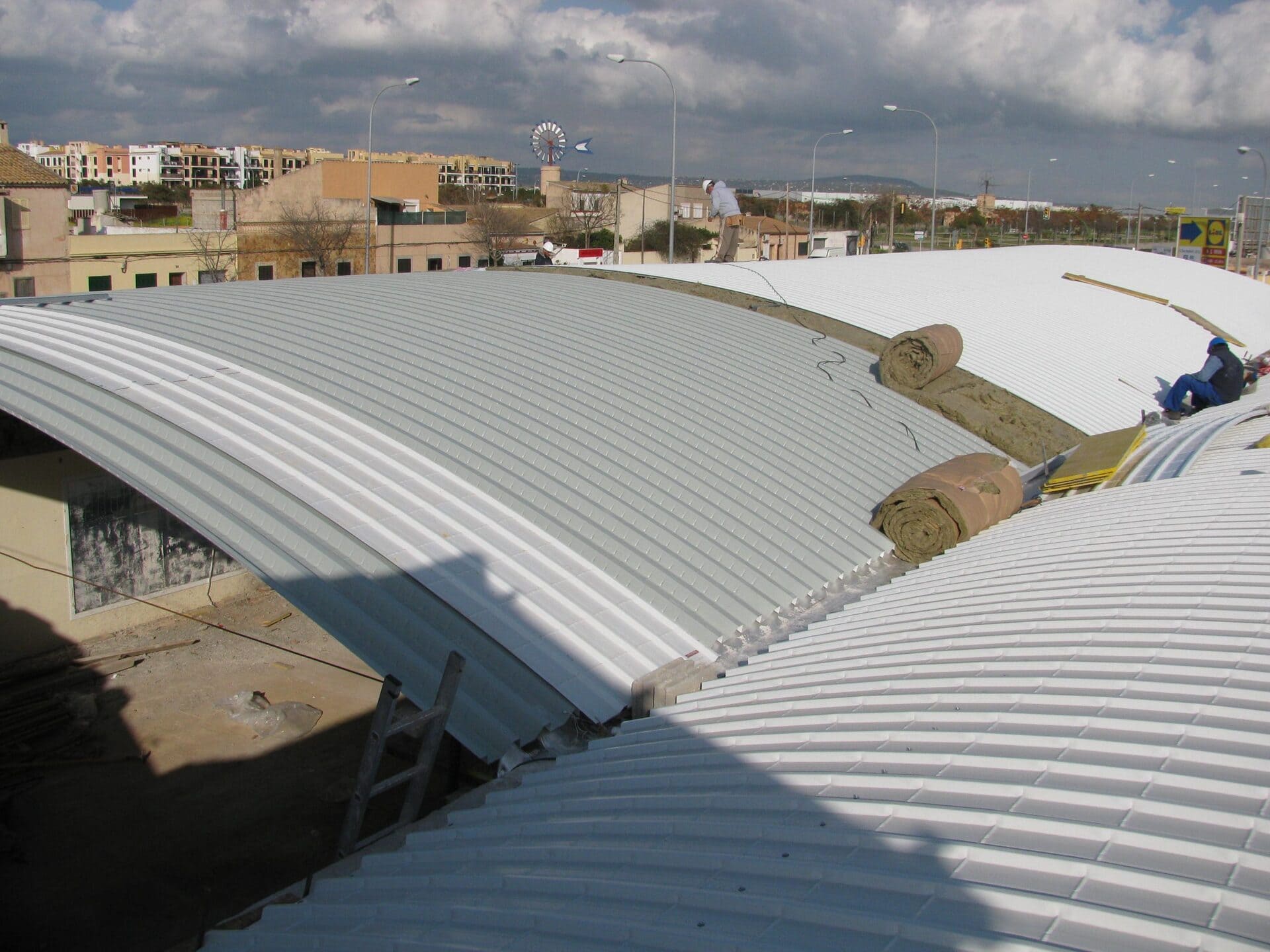

The different encounters of curved finishing are resolved by means of longitudinal pieces of sheet metal, shaped and curved by folding. These finishing pieces will adjust to the characteristics of each meeting and roof solution and, therefore, their dimensions will have to be defined for each project. They are available in both galvanized steel and the different colors of pre-lacquered galvanized steel, and in thicknesses from 0.60 mm to 1.20 mm.

The most common cross-cutting encounters are:

- Curved ridge cap trim to close the meeting between the vertical wall and the curved roof.

- Curved side wall trim to close the meeting between the side slope skirt and the façade, generally of a roof parapet.

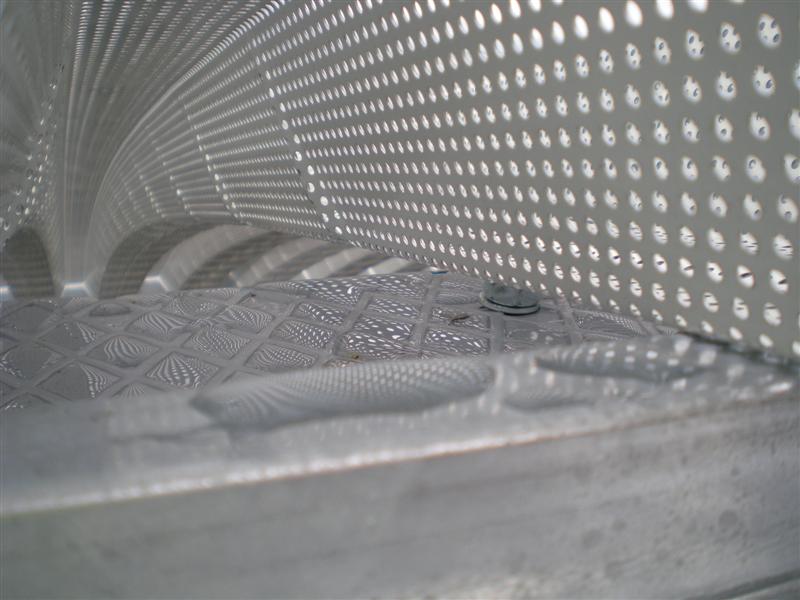

- Curved skylight trim for the interior closure of the smooth cellular polycarbonate skylight.

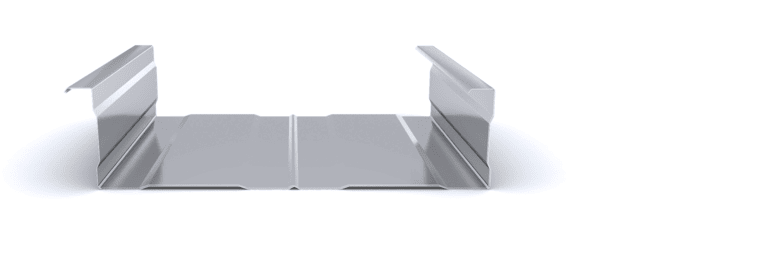

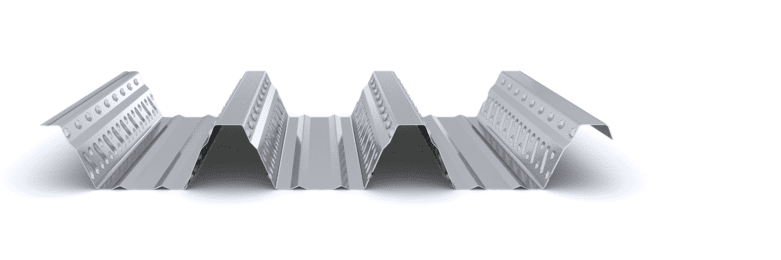

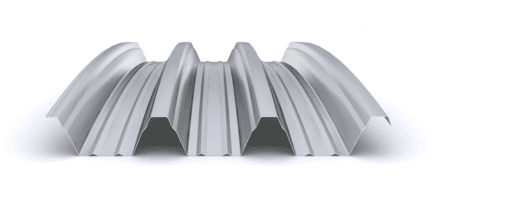

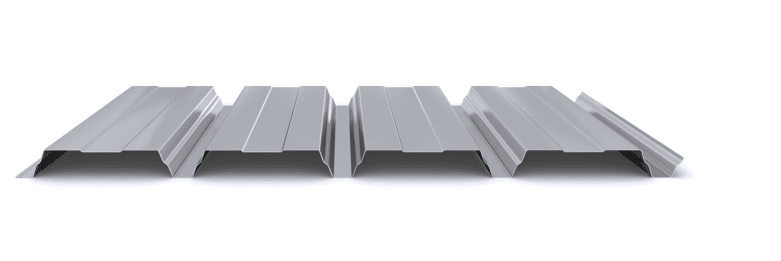

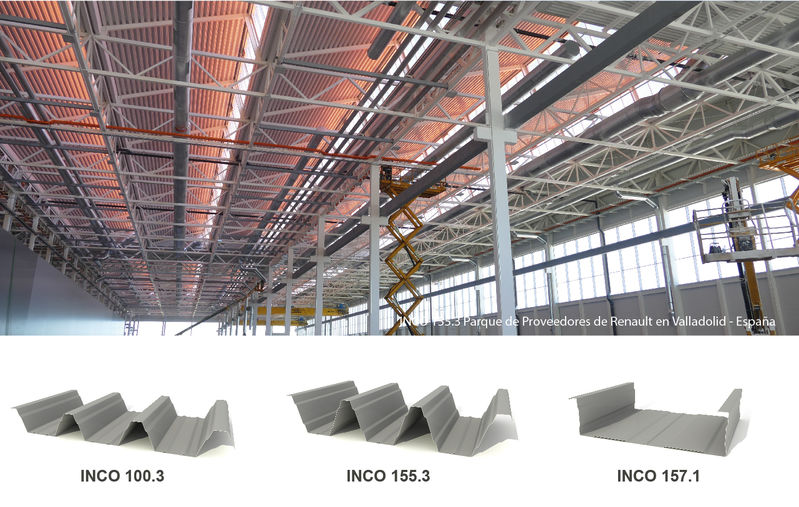

The finishing applied in the collaborative slab solution serves to form the perimeter of the slab and act as a containment element for the concrete. They are made using longitudinal pieces of sheet metal, formed by folding and are made up of two pieces: one perimeter of the height of the slab, which acts as formwork, and another as a brace fixed to the collaborating profile, which supports the thrust of the concrete. The perimeter finishes are placed on the perimeter beams or the openings before assembling the sheet metal. They are available in galvanized steel.

The most common finishes in the collaborative forging solution are:

- The perimeter trim or edge trim is formed by C-section pieces with a minimum thickness of 1,00 mm.

- The brace trim is made up of pieces whose length depends on the edge of the slab, with a width of 40 mm and a thickness of 1,00 mm.